Troubleshooting powerhook – Poweramp POWERHOOK P4111-0010 5.2006 User Manual

Page 46

44

4111-0010 — December 2004

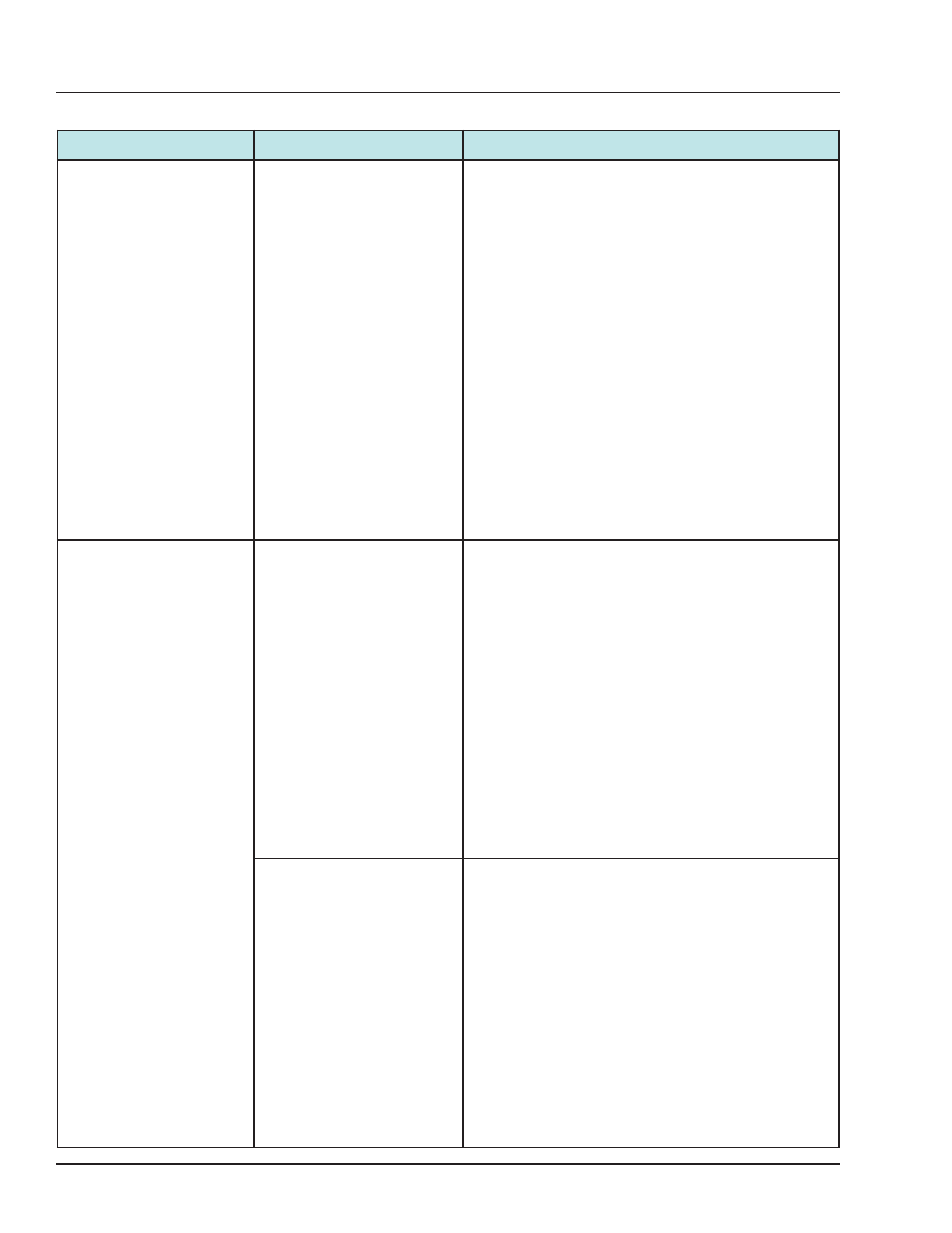

TROUBLESHOOTING POWERHOOK

Symptom

Possible Cause

Solution

Lowered restraint

returns to fully retracted

position but unit does

not automatically shut

OFF.

Pump Operates in

pressure relief.

Restraint remains

lowered.

Proximity switch on rear of

(closest to rear pit wall)

guide track that senses

when restraint fully retracted

out of adjustment.

Locate switch on rear of guide track. Observe

indicator light at controller input (#6) that receives

signal from switch. Input light should turn OFF when

restraint fully extended. If this does not occur:

-Check switch position, loosen two guide track

mounting bolts, tap guide track assembly back

towards rear pit wall.

-Switch should be positioned approximately 1/4”

from the inside wall of the track. Make sure that the

switch face does not extend further than the guide

track mounting bars welded to the cylinder. Position

switch so that face will not come into contact with

guide rod.

-Tighten nuts to secure switch. NO NOT overtighten

nuts. Maximum tightening torque is 25 lb/ft.

-Run restraint. Make sure motor shuts off when

hook is in stored position. If motor does not shut off,

reposition guide track slightly forward of current

position.

Restraint fully retracted

but does not raise, even

when ON-OFF switch

turned OFF.

Solenoid “D” valve stuck

ON.

Locate solenoid (See Parts: Valve Block).

Remove coil from cartridge valve and cartridge valve

from valve block.

-Check valve for contaminant's and/or damage.

-Replace valve if damaged.

Carefully wipe valve with clean rag (do not damage

“O” rings on valve.

-Check valve block for contaminant's.

-Replace valve and coil.

NOTE: Do not overtighten valve into block. Max Torque:

30-40 lb/ft. or snug to prevent leakage. Tighten coil snug,

avoid overtightening and causing valve to bind.

Operate unit. Replace valve if problem persists and

all other troubleshooting procedures performed.

Binding inside positioning

cylinder.

Locate positioning cylinder. Place pan under hose

connected to cylinder to catch fluid.

SLOWLY loosen hose since fluid may exit cylinder

rapidly (cylinder is spring loaded with spring

compressed when lowered). A cylinder that is not

binding will raise as fluid leaves the cylinder. A

cylinder that is binding will remain lowered, even

when the hose is completely removed from the

cylinder.

Replace a cylinder that is binding.