Maintenance, Important – Poweramp POWERSTOP SERIES User Manual

Page 21

19

4111-0014 — July 2013

MAINTENANCE

Daily Maintenance

• Daily clear any debris to prevent operation issues.

• Check inside and outside lights for proper

operation

Weekly Maintenance

• Operate the vehicle restraint through the complete

operating cycle to maintain lubrication of parts of

both mechanical and hydraulic restraints.

• Inspect the rear vertical track area (C). The track

area must be kept free of dirt and debris.

• Clear any debris to prevent operation issues.

• Check inside and outside lights for proper

operation

• Operate the vehicle restraint through the complete

operating cycle to maintain lubrication of parts of

both mechanical and hydraulic restraints.

• Inspect the rear vertical track area (C). The track

area must be kept free of dirt and debris.

• Clean and lubricate scissors assembly (A) and all

pivot points.

• Make sure Rear Track Assist Spring (D) is properly

seated at the bottom of the rear track.

Yearly Maintenance

• Repeat of Quarterly Maintenance.

• Change Hydraulic Oil (May be required earlier

depending on conditions).

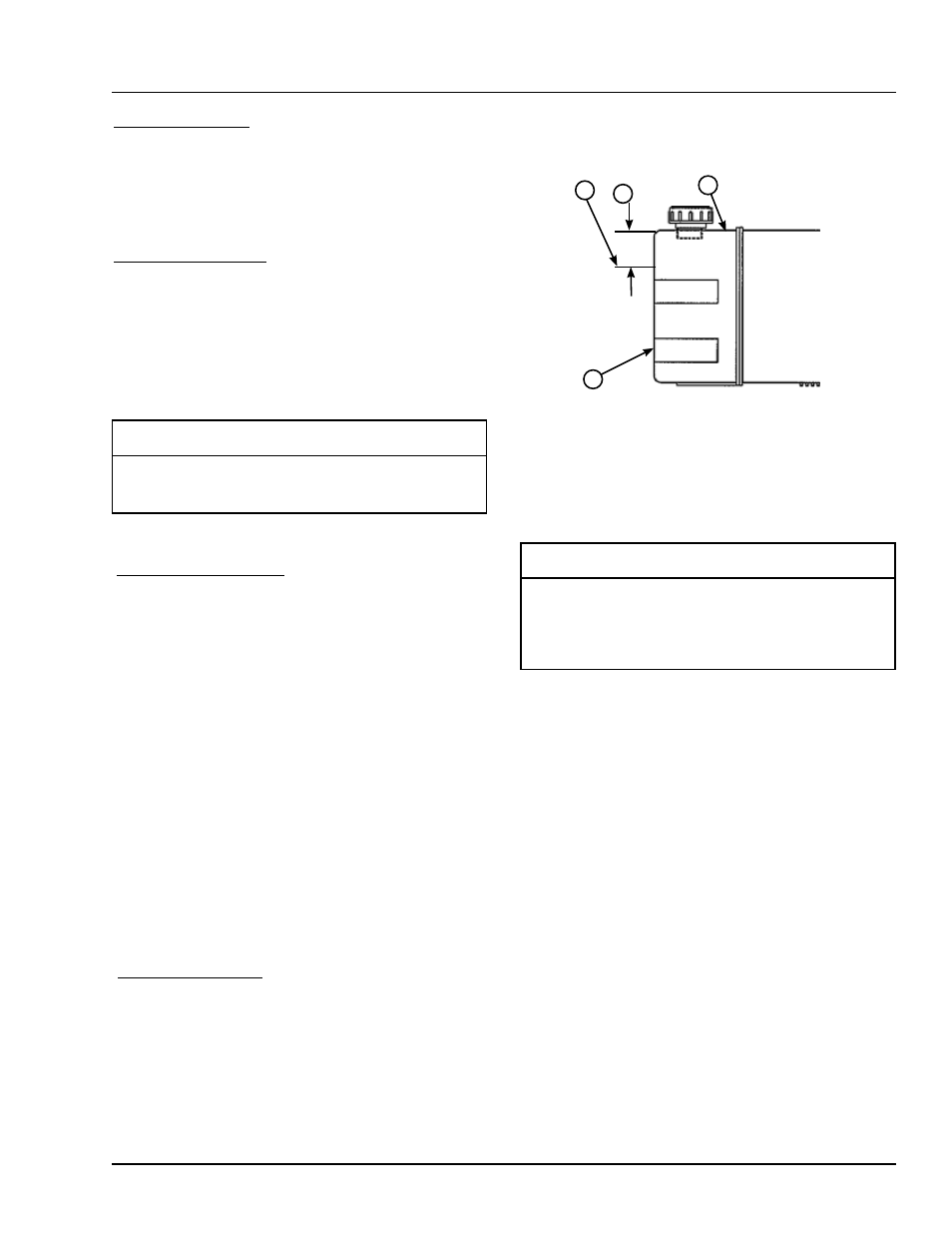

M — Reservoir

N —1 in. (25.5 mm) (From Top of

Reservoir)

P — Breather Cap

Q — Fluid Level

• Check reservoir fluid level (Q):

1. Put the vehicle restraint in the stored position.

2. Turn OFF all electrical power to the vehicle

restraint.

3. Wipe off plastic tank as needed (P).

4. Measure fluid level. The fluid level should be

approximately 1 in. (25.5 mm) (N) from top of

reservoir (M) with vehicle restraint stored.

5. Add hydraulic fluid if necessary. Use only

recommended fluid. See previous page.

6. Install cover

7. Turn ON electrical power.

*Refer to OSHA regulation 1910.147.

Quarterly Maintenance

IMPORTANT

A low fluid level or the use of hydraulic fluids not

equivalent to the fluid types recommended, will

cause abnormal operation of the leveler and WILL

void warranty.

IMPORTANT

Failure to clean and properly lubricate the vehicle

restraint will cause abnormal operation.

M

Q

P

N