Fig. c – Mastercool 99663*A HVAC Digital Manifold User Manual

Page 4

CLAMP-ON THERMOCOUPLE CALIBRATION (PAIRING)

Each thermocouple has been calibrated (paired) to this manifold in the factory for accurate

readings. Replacing the thermocouple will require pairing. Please follow the directions

indicated.

1. Connect the thermocouple to the manifold and attach the clamp to an accurate source

of temperature (reference source.)

2. Remove the rubber cap from the back of the manifold (located next to the battery

compartment under the rubber boot.)

3. Use a flat miniature screwdriver to adjust the temperature.

4. Replace the plug.

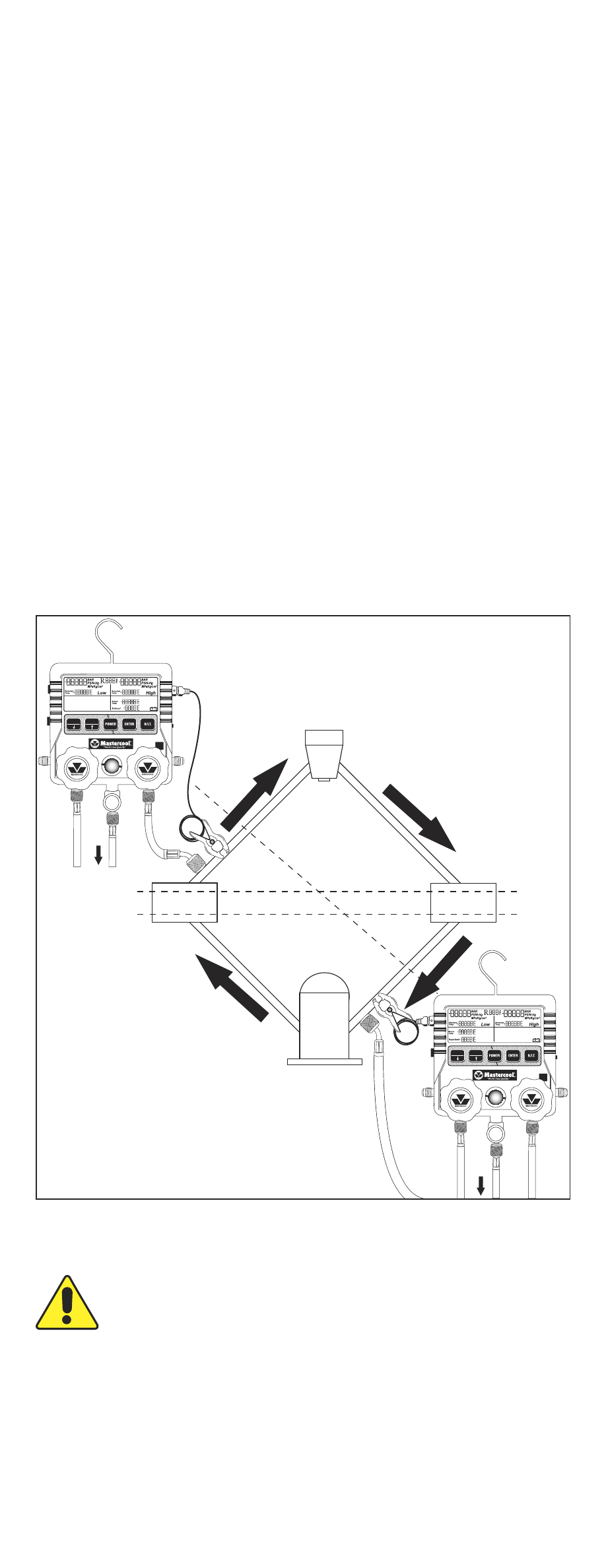

MEASURING ACTUAL SUPERHEAT AND SUBCOOLING

(SEE FIG. C)

Superheat is the difference between the actual temperature (sensor temperature) of

the refrigerant (gas) as it leaves the evaporator and the boiling point temperature of the

refrigerant in the evaporator coil

(saturated temperature). After boiling, the refrigerant

continues to warm up. The number of degrees it “warmed up” after boiling is called the

superheat. Under worst-case conditions (low load for fixed orifice systems), the refrigerant

in the evaporator boils off near the end of the evaporator coil. To make sure liquid doesn’t

enter the compressor under the worst case condition, the AC manufacturers publish charts.

The charts indicate what the superheat should be at a given indoor wet bulb measurement

and outdoor air temperature. Measuring superheat is your best indication on a fixed

orifice system of the proper refrigerant charge and operating conditions. If everything else

is working properly and the actual superheat is too high, add refrigerant. If it’s too low,

remove refrigerant.

Subcooling is the difference between the boiling point of the refrigerant in the condenser

(saturated temperature) and the actual temperature (sensor temperature) of the

refrigerant as it leaves the condenser. The degrees that the refrigerant “cools down” below

the boiling point is the sub-cooling. Under worst case scenario low load for thermostatic

expansion valve systems (TXV) the subcooling will continue to rise. If the subcooling rises

too high, liquid may be backed into the compressor causing damage and failure.

On TXV systems, the subcooling is the best indication of the state of the charge in the

refrigerant system since these systems are designed to maintain constant superheat.

Properly charging a system ensures maximum efficiency and longer equipment life.

Use caution whenever working with electricity and

high-pressure liquid or gas. Always wear safety glasses.

Follow all instructions provided with equipment being serviced or installed.

TARGET SUPERHEAT AND SUBCOOLING

Follow all equipment manufacturer’s specifications, warnings and suggestions.

To determine the target superheat (fixed orifice system) or subcooling (charts vary

dramatically from one system to another), you will typically need three things. Outdoor dry

bulb (outdoor air temperature), indoor wet bulb, and the manufacturers target superheat

chart or subcooling chart.

You can use Mastercool part number 52232 Humidity Temperature Meter for both indoor

5

��������

������

�

�

���������

����������

����������

���������������������������������������������

������

����������������

�����

������

����������������

�����

������������������������������

����������

��

�������������

���

���������������

�

����������������

����������������

����������������

����������

��

�������������

���

������������������������������

������

�������

������

�������

������

������

������

������

FIG. C

www.mastercool.com