Adjustable / retractable flow element assembly – Fluid Components International GF03 User Manual

Page 10

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

Model GF03 Flow Meter

6

Doc. No. 06EN003352 Rev. B

Verify Serial Numbers

Verify the flow element and flow transmitter have the same serial number, as they are to be

installed as a matched set.

Verify Dimensions

Verify the flow element and flow transmitter dimensions as shown in Appendix A.

Verify Flow Direction for Flow Element Orientation and Placement

Note:

Correct flow element placement in the measurement stream is vital for obtaining

accurate flow readings. Before mounting the flow element, check the options

ordered for correct orientation and insertion length at the planned site of installation.

The flow element thermowells must be positioned in the same orientation to the process flow

as they were during calibration (refer to the Instrument Information Sheet). Failing to install

the flow element correctly may reduce the accuracy of the flowmeter. Be sure the flow arrow

points in the direction of flow.

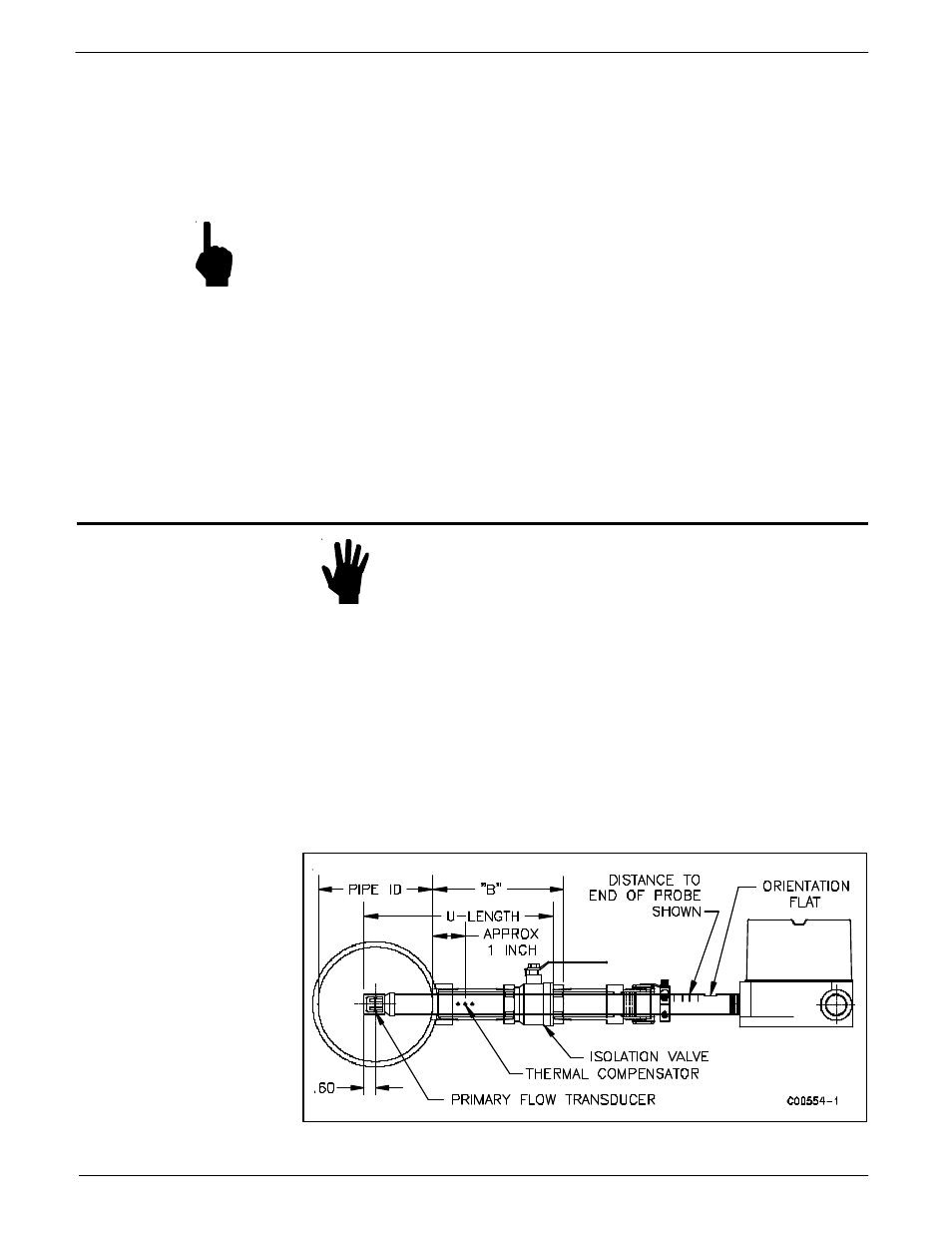

The flow element thermowells are to be placed as shown in Figure 3, with the end of the

shroud 0.6 inches past center line.

There is a flat area machined perpendicular to the thermowell plane. Adjust the flow ele-

ment during installation so the flat area is parallel, with in ±2°, to the direction of process

media flow.

Caution:

Do not over-tighten the flow element. The RTD's can be

dammaged if the flow element is forced into the far wall of the

pipe or vessel.

Adjustable / Retractable

Flow Element Assembly

Select one of the following installation procedures which is applicable to the unit being

installed.

NPT and flange packing gland mounts are available. The valve assembly with appropriate

connections are typically customer supplied. Follow the pipe or flange mounting procedure

below.

NPT Pipe Mounting

w

Apply sealant compatible with the process media to male threads. Carefully insert into

process mount. Threads are right-handed. Tighten with an open-end wrench on the

hexagonal surface provided. Rotate until snug.

Figure 3 - NPT Pipe Mount