Product description, Installation for dispenser cutoff – Franklin Fueling Systems DC404-4 Controller User Manual

Page 3

3

Product Description

The DC400 system uses a sump sensor to detect the

presence of liquid in the STP (Submersible Turbine Pump)

or dispenser sump. If liquid is detected, the system will

shut down power to the STP or dispenser.

The DC400 system consists of the 404-4 Controller and

either a 2-Wire or 3-Wire sensor. Follow these instructions

for installation of the 404-4 Controller. Franklin Fueling

Systems sensors approved for use with the DC400 system

come with their own installation instructions.

Specifications:

Input line voltage:

90 – 250VAC 50/60 Hz

404-4 power consumption:

2W

Relay switch configuration:

SPST

Relay switch contact rating: 12A continuous, 250VAC

maximum

Operating temperature:

-20 to 60 degrees C

Hazardous location

category:

Class I, Div 1, Group D

Refer to Franklin Fueling Systems control drawing 000-1737

Installation for Dispenser Cutoff

Notice! Only qualified service

technicians experienced with petroleum

dispensing and pumping systems

should install the DC400 system.

Notice! Do NOT exceed the 12A

(continuous), 250VAC relay contact

rating of this controller. Relay contacts

are not fused.

Note: Install this kit ONLY in a UL listed dispenser.

Note: If the is no junction box or open port on the junction

box, you cannot install this kit.

1. Shut off all power to the dispenser. Lock out and

tag the corresponding dispenser circuit breaker.

2. Open / remove the dispenser lower panel for

access to the dispenser hazardous area. Inspect

the hazardous area to locate the dispenser

explosion proof power entry junction box. The 404-

4 controller will be wired into the dispenser via a

spare conduit hub located on the dispenser power

entry junction box.

3. Determine where to best locate the 404-4

controller and how best to plumb conduit from

the dispenser spare conduit hub to the 404-4

controller. The 404-4 controller must be located

so that regular servicing of the dispenser (such as

changing of fuel filters) will not be impeded. The

404-4 controller can be located in the dispenser

hazardous area or suspended down below the

dispenser in the dispenser sump as room dictates.

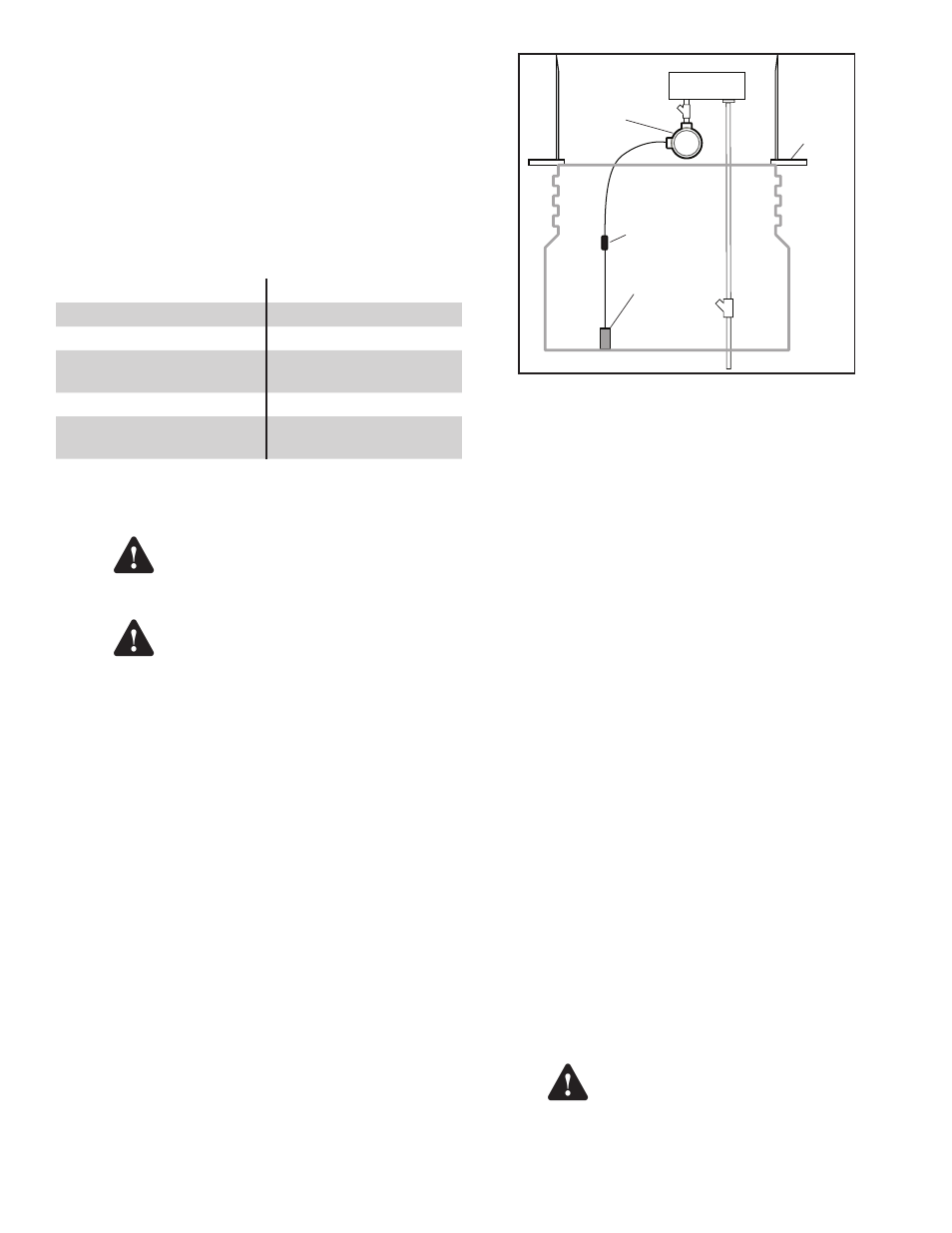

Refer to figure 1.

404-4

Controller

2-Wire or

3-Wire sensor

Dispenser

Junction Box

EYS

Dispenser

Sump

Cable Connection

Dispenser

Base

EYS

Figure 1: Typical System Installation in a Dispenser Sump

Note: Because each dispenser installation is unique it is

impossible to provide a “one size fits all” conduit

fitting kit. Necessary explosion-proof conduit and

conduit fittings must be determined and supplied by

the installer. The 404-4 controller conduit size is 3/4”

NPT. Simple fittings such as elbows, sweeps, unions,

and nipples should be used and must be UL listed and

suitable for use in Class I, Div 1, Group D locations.

4. Open the dispenser power entry junction box

cover and retain hardware for later use. Remove

spare junction box plug and plumb explosion-proof

conduit from the spare conduit entry hub to the

404-4 controller power port (the port with 6 wires

protruding). Thread the 6 wires coming out of the

power port of the 404-4 controller through the

conduit to the dispenser power entry junction box.

Important! Be sure installation of conduit, fittings and

wiring is in accordance with local, State and

National electrical codes. A conduit seal must be

installed between the dispenser J-box and the

controller. The conduit seal must be within 18" of

the dispenser J-box and the 404-4 controller. Refer

to NEC NFPA 70, article 501.15 (A) (3), 2011. Make

sure the dispenser power entry junction box has

enough spare room to accommodate the additional

404-4 controller wires (see the table on page 2).

Important! When tightening the conduit to the 404-4

controller, use a wrench on the conduit fittings and

not the 404-4 controller body.

5. Wire the 404-4 power wiring per the schematic

that matches your dispenser listed in Figures

7 - 14. Contact your dispenser manufacturer for a

wiring diagram if you are unsure of the dispenser

input power wiring.

Make sure to connect both ground

wires and verify they are connected

to earth ground. Failure to do so may

result in a fire or explosion hazard in

case of a fault condition.

Warning

Warning

Warning