Unique valve head, Transmount, Mass transmount – Veris Verabar Brochure User Manual

Page 3: Field flow systems, The proof of verabar accuracy, Partial insert, Spring-lock… offers a superior mounting method

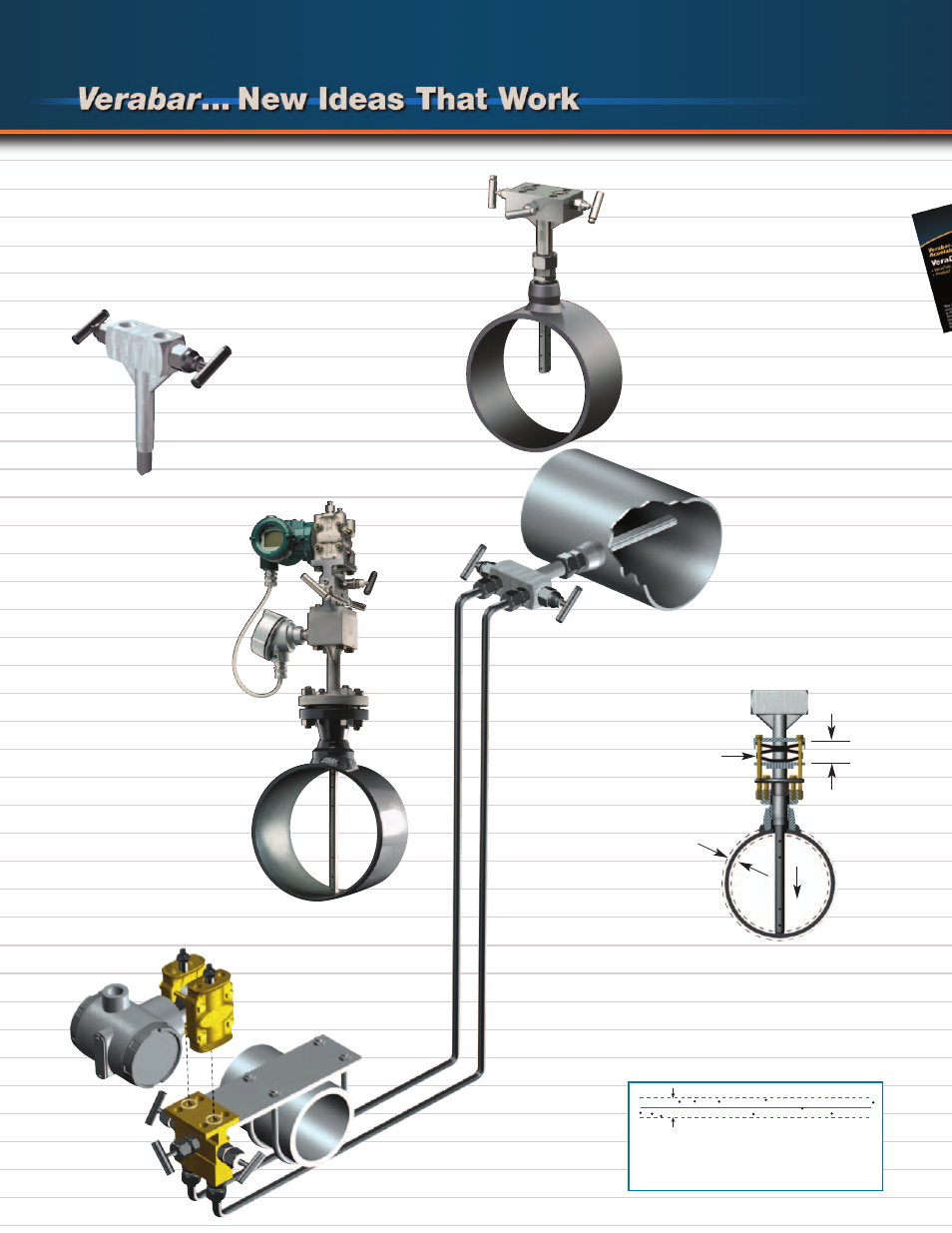

Unique Valve Head

Verabar offers a new concept…

built-in valves in the head of the

instrument.

This superior design:

•

Simplifies installation and

maintenance.

•

Lowers the

connecting

hardware

cost by

reducing the

number of

fittings.

Transmount

A Transmount flow system

is the first choice for all

liquids; and for gas and

steam applications, with

slight variations in pressure

and temperature.

Mass

Transmount

A Mass Transmount flow

system should be selected on

steam and gas applications

with variable temperature

and pressure.

Field Flow

Systems

Ready to install, the

Verabar can be ordered

with a manifold, transmitter

or local indicating

meter.

The Proof of Verabar Accuracy

Accurate Flow Coefficients

The true test of a flow measurement device is its ability

to repeat its published flow coefficient within its accuracy

band.

Verabar

has been

thoroughly

tested at

independent

flow laboratories

(all sensor sizes, in

multiple pipe sizes,

in gas and liquids).

Spring-Lock

Complete

Installation

in Less than

an Hour

Partial Insert

•

Designed specifically for

high velocity cooling water

applications, large diameter

pipes, large vertical stacks

and buried water lines

•

Extends 1/3 into pipe to

reduce procurement

and installation

costs — specifically

useful when a

hot tap is required

•

Partial Insert hot

tap sensors can be

inserted/retracted with

no reduction in flow rate

Spring-Lock…

Offers a Superior Mounting

Method

This advanced, patented design ensures

the sensor remains sealed, locked and

pre-loaded to the opposite wall regardless

of changes in pipe diameter due to pres-

sure, temperature or mechanical force.

This design has important advantages:

•

Fugitive emission and leak prevention…

The Spring-Lock continually compen-

sates for the differential in packing and

body growth rates due to increased

temperature.

•

Increases sensor strength,

thereby eliminating the

need for an opposite wall

support. A locked, pre-

loaded sensor is four

times stronger than

a non-preloaded,

cantilevered sensor.

•

Other mounting methods

do not pre-load the sensor

or the packing seal and are subject to

increased sensor vibration, metal fatigue,

breakage and leakage.

0.74

.073

0.72

0.71

K 0.70

0.69

0.68

0.67

0.66

0

5

10

15

20

25

Velocity (fps)

Test Location: Utah water Research Laboratory

Test Data: November 13, 1991

Fluid: Water at 60 deg F

Meter Size: 6 inch, Schd 40, -10

Serial No: V1000.05.1

±1.0%

Visual load

indicator

Spring

travel

Compensates for

changes in pipe

diameter

Actual Flow Test