Trouble shooting – M&C TechGroup CSS-M Operator's manual User Manual

Page 21

4-2.1.3-ME

Gas sampling and gas conditioning technology

21

17

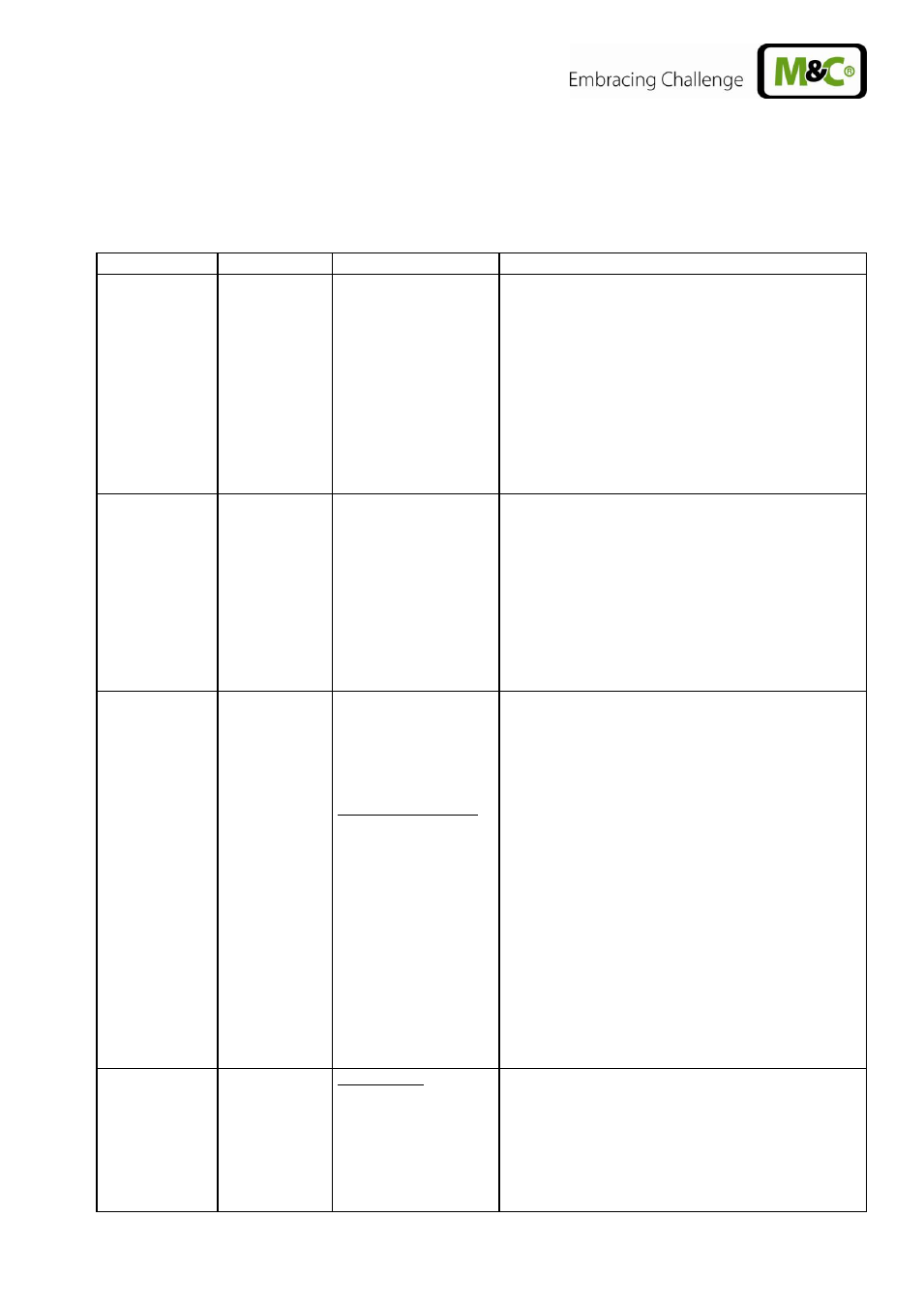

TROUBLE SHOOTING

The following table shows possible sources of errors and how to remove them (not applicable for the

starting-up phase).

Display

Fault

Possible cause

Examination/Correction

None

No supply voltage;

Check the supply voltage according to the type

plate;

ok?

Control whether the mains plug is put in correctly or

whether the main switch is in position „1“;

ok?

Examine the fine fuses F1, F2 on the internal

board;

ok?

LED K1 is

beaming

permanently

and temp. >

8°C

Cooler alarm „Excess

temperature“; cooler

switches the sample

gas pump

automatically off;

Ventilator does not

function

Ambient temperature too high;

ok?

Free convection inside the gas conditioning unit

upset internal temperature too high;

ok?

Sample flow or dew point too high? Reduce flow.

ok?

Return the instrument for repair to M&C.

Temp.

>2°C and

< 7,5°C

Cooler runs,

sample flow is

interrupted;

Alarm-LED in

front panel is

beaming red

(see 4)

Pump

defective

Diaphragm pump

does not work;

Pump is not switched

on

Liquid alarm sensor:

Sensor turns sample

gas pump

automatically off;

Switch in position „on“ (is beaming green)

Ok?

LED Liquid alarm is beaming red.

Liquid in the filter (Dry filter and liquid alarm sensor

and check peristaltic pump, see below.)

ok?

Check the hoses for condensate draining;

ok?

Check pump hose (see 15.3.1);

ok?

Check pump SR25.2 (see 15.3);

ok?

Return instrument for repair to M&C.

Pump works,

but sample

gas flow is

interrupted;

Flow meter :

Needle valve is shut.

Sample probe or

sample hose clogged

or line squeezed;

Set the desired flow rate on the needle valve.

Loosen the sample hose from the sample gas inlet

of the gas conditioning unit (see 12.1);

Gas flow?

Clean the clogged line or replace it;