PVI Industries SU-3 User Manual

Page 14

14

PV500-56 06/12

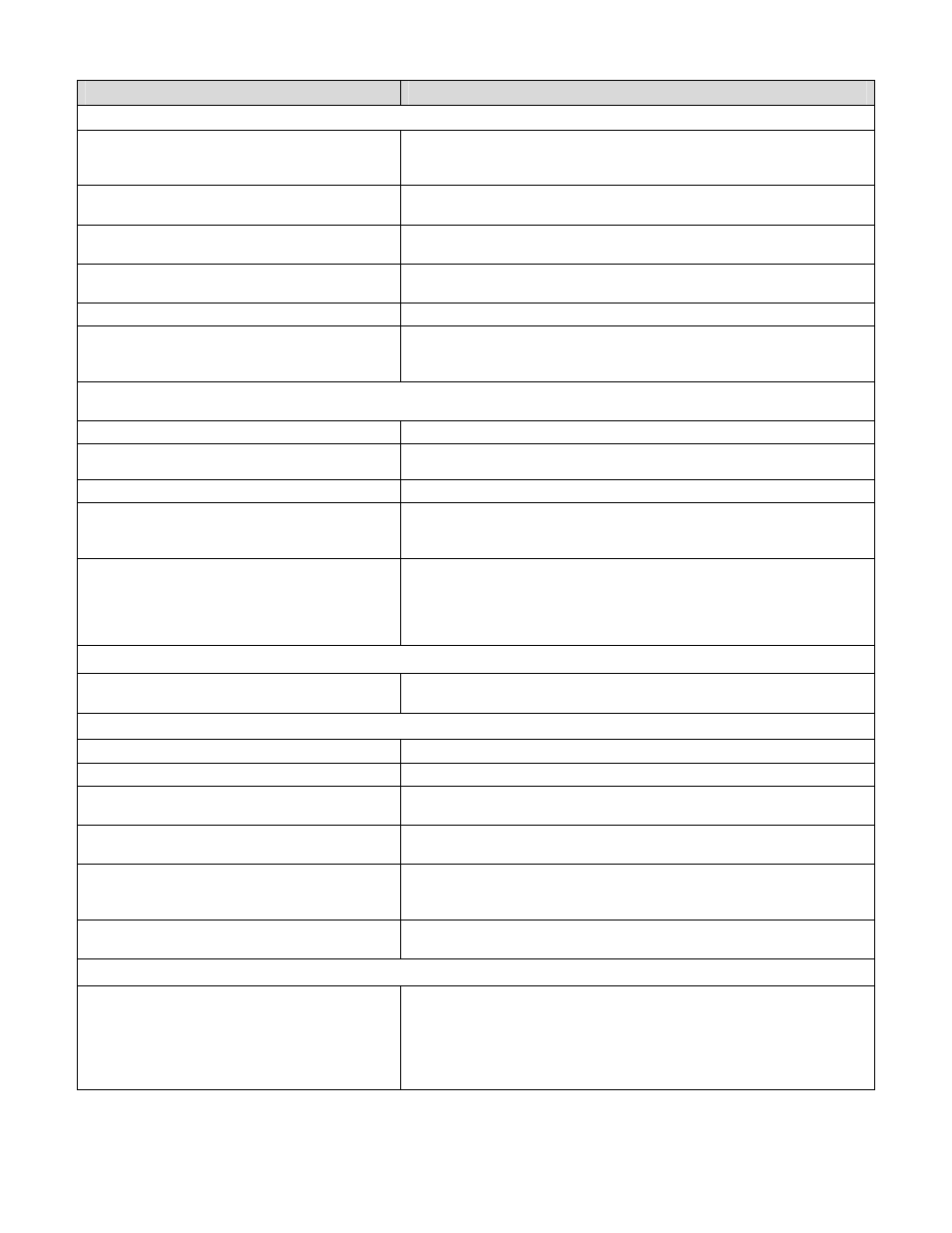

12. TROUBLESHOOTING

Condition

Solutions

1. Burner motor runs and:

No flame after pre-purge

Check 24V feed to airflow switch & after airflow switch to control. Fix or

replace the airflow switch. If there is no secondary power, then replace

the 24V transformer.

No flame, faulty ignition transformer or spark

separately

Check ignition transformer output from Honeywell control and check for

cracked electrode or gap. Fix or replace.

Burner locks out after 4 seconds

First, check ionization electrode, ionization cable (for cracks) and boot.

Fix as needed.

Polarity

reversed

Check power feed for reversed polarity following instructions in the

Commissioning Checklist, Section 10.1.

Bad earth grounding

Fix the ground wire.

Gas supply pressure is too low

Check the gas supply regulator and adjust to proper pressure, check that

gas piping is adequately sized following the instructions in Section 6, Gas

Supply and Piping.

2. Pulsation – * Follow the instructions in Section 10, Burner Setup and Adjustment and using a combustion analyzer,

readjust combustion air as required to obtain proper combustion.

Gas pressure is too high.

Use manometer and readjust the inlet pressure. *

Manifold pressure too high

Use manometer and readjust regulator for correct manifold pressure.*

Burner is dirty

Clean burner.

Venting is inadequate

Adjust barometric damper, clear flue and cap of foreign materials or

correct vent system following the instructions in Section 5, Venting, to

provide draft within the specified range.

Misadjusted burner head

First correct by steps above, if still pulsating, adjust to a lower head

position number. Manifold pressure must be readjusted to match that

shown on the burner information decal and combustion must be

rechecked following the instructions in Section 10, Burner Setup and

Adjustment.

3. Burner

locks

out

Ionization current is too low

Check current. Minimum 0.8 micro amps. Check position of ionization

electrode and the condition of the cable.

4. The CO content is too high

Excess air is too low or possibly too high

Adjust air shutter.

The gas holes in pressure plate are clogged

Clean them.

The fresh air intakes are too small

Increase the size of combustion air openings to those specified in Section

4, Combustion and Ventilation Air.

Negative pressure in mechanical room

Remove source of negative pressure and/or increase size of combustion

air openings.

Gas supply is too high or too low

Check the gas supply regulator adjust to proper pressure, check that gas

piping is adequately sized following the instructions in Section 10, Burner

Setup and Adjustment.

Burner settings or adjustment incorrect

Follow the instructions in Section 10, Burner Setup and Adjustment and

using a combustion analyzer.

5. Condensation in the heat exchanger

Firing Rate is too low

Check burner combustion. If combustion is in range, increase firing rate

so the gross stack temperature is at least 350

o

F (177

o

C) by adjusting to

a higher head position number. Manifold pressure must be readjusted to

match that shown on the burner information decal and combustion must

be rechecked following the instructions in Section 10, Burner Setup and

Adjustment. If allowed by code and vent manufacturer, insulate the vent.