Specifications – Shure AUDIO PROCESSOR WITH FEEDBACK REDUCTION DFR22 User Manual

Page 11

ENGLISH

9

SPECIFICATIONS

Frequency Response

20 Hz to 20 kHz ±1 dB

Dynamic Range

110 dB minimum, A-weighted, 20 Hz to 20 kHz

Sampling Rate

48 kHz

Digital-to-Analog, Analog-to-Digital Conversion

24 bit

Impedance

Input: 10 kΩ

Output: 120 Ω

Input Clipping Level

+24 dBu minimum

Output Clipping Level

+24 dBu

+12 dBu (with 12 dB pad)

+6 dBu (with 18 dB pad)

Total Harmonic Distortion

< 0.05%, +4 dBu, 20 Hz to 20 kHz

Propagation Delay from Input to Output

<1.5 ms

Polarity

Input to output: non-inverting (inverting optional)

Operating Voltage

100–240 Vac, 50/60 Hz (auto-switching), 1 A, maximum

Maximum Power Drain

45W

Temperature Range

Operating: –7_ to 49_ C (19_ to 120_ F)

Storage: –29_ to 74_ C (–20_ to 165_ F)

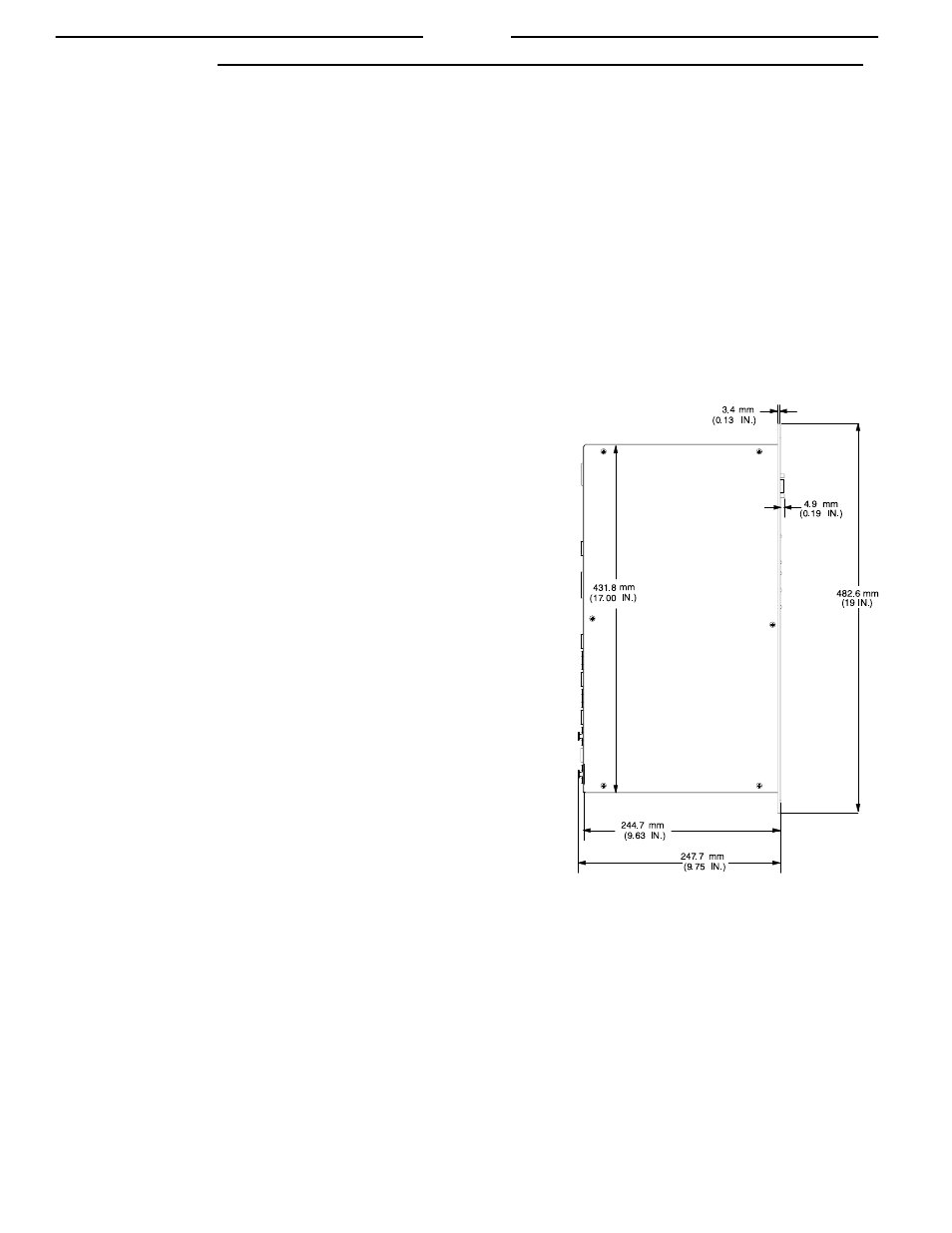

Dimensions

482.6 mm x 247.7 mm x 44.4 mm (19 in. x 9.75 in. x 1.75 in.)

(See Figure 18)

Weight

2.83 kg (6.25 lbs)

Furnished Accessories

Power Cable (DFR22)

95

B8389

. . . . . . . . . . . . . . . . . . . . . . . .

Power Cable (DFR22E)

95

C8247

. . . . . . . . . . . . . . . . . . . . . . .

5-pin DIN Shure Link Cable

95

B8676

. . . . . . . . . . . . . . . . . . . .

Hardware Kit

90A

Y8100

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 Block Connector Terminals, 3-pin

(for audio inputs and outputs)

2 Block Connector Terminals, 10-pin

(for control inputs and outputs)

4 Rackmount Screws and Washers

Optional Accessories

DRS10 Wallplate unit with 10-position rotary switch for preset

control

Certifications

cULus. Listed and cUL Listed to UL 6500 and CSA E60065. Au-

thorized under Verification provision of FCC Part 15 as a Class B

Digital Device.

This Class B digital apparatus complies with Canadian ICES–003.

Conforms to European Union Directives, eligible to bear CE

marking. Meets European Union Low Voltage Requirements:

Certified to EN 60065. Meets applicable tests and per-

formance criteria in European Standard EN55103 (1996) parts 1

and 2, for residential (E1) and commercial and light industrial

(E2) environments.

NOTE: EMC conformance testing is based on the use of sup-

plied and recommended cable types. The use of other cable

types may degrade EMC performance.

EMC conformance testing is based on the fact that the computer

is used for setup purposes only and disconnected during EMC

testing.

DFR22 DIMENSIONS

Figure 18