The scope and suggestions for uses, How to select tightening torque – InFocus DS 14DVF User Manual

Page 20

English

20

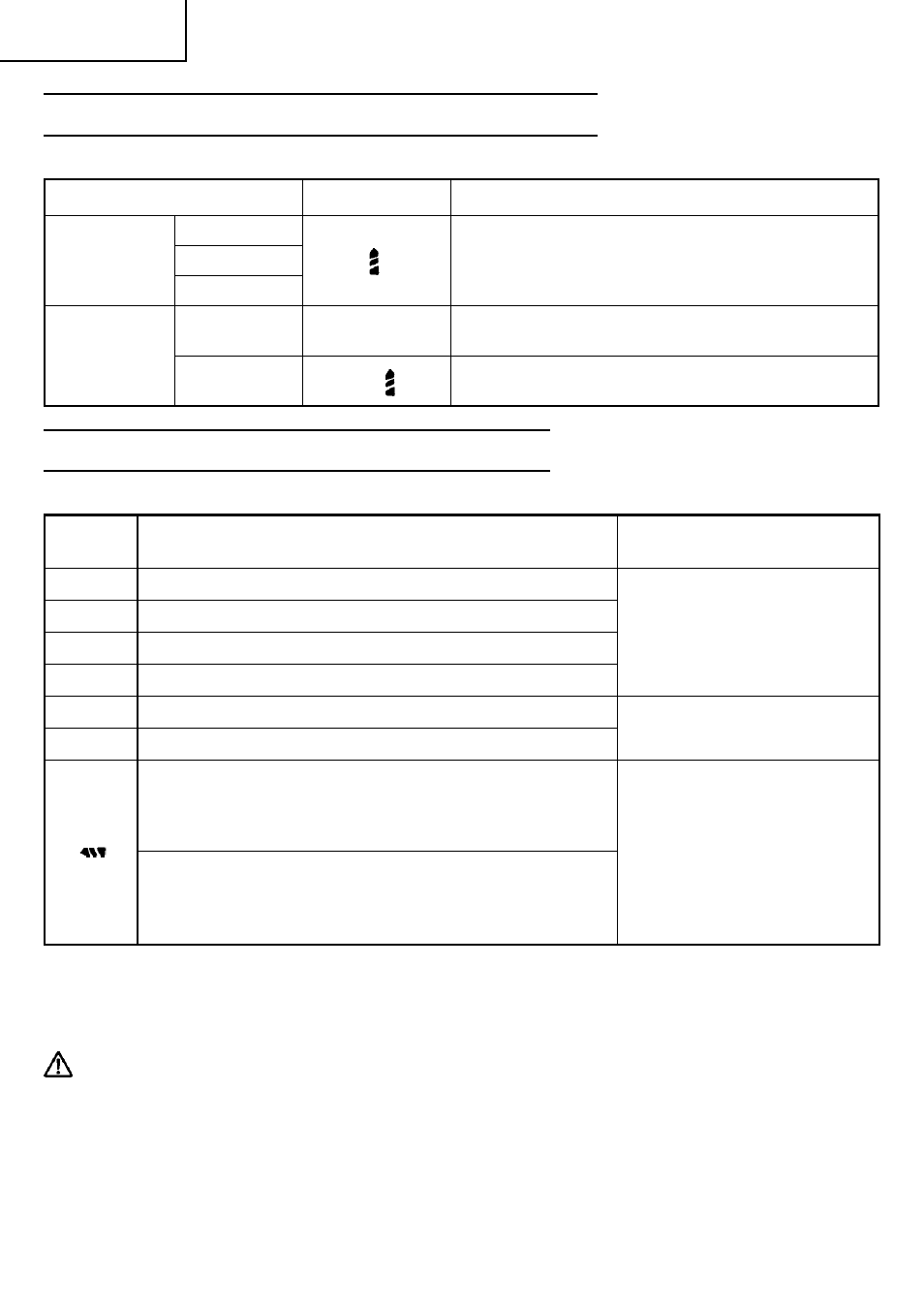

THE SCOPE AND SUGGESTIONS FOR USES

Table 3

HOW TO SELECT TIGHTENING TORQUE

Table 4

NOTE:

The selected content shown in Table 4 indicates the differences according to screw type,

screw size and material used.

CAUTION:

ⅷ While operating the Cordless driver drill, take care not to lock the motor.

If the motor is locked, immediately turn the power off.

If the motor is locked for a while, the motor or battery will be burnt.

ⅷ Do not tighten too strongly as the screw heads will be damaged.

Work

Cap position

Suggestions

Wood

Drilling

Steel

Use for drilling purpose.

Aluminum

Screw

Machine

1 – 22

Use the bit and socket matching the screw

tightening

screw

diameter.

Wood

1 –

Use after drilling a pilot hole.

screw

Cap

Tightening torque

Operation example

position

Approximately 9 in-lbs. (10 kg-cm)

Approximately 15 in-lbs. (17 kg-cm)

Approximately 23 in-lbs. (26 kg-cm)

Approximately 35 in-lbs. (40 kg-cm)

Approximately 43 in-lbs. (49 kg-cm)

Approximately 52 in-lbs. (60kg-cm)

High speed: approximately 61 in-lbs.

(70 kg-cm)(DS12DVF)

approximately 70 in-lbs.

(80 kg-cm)(DS14DVF)

Low speed: approximately 191 in-lbs.

(220 kg-cm)(DS12DVF)

approximately 213 in-lbs.

(245 kg-cm)(DS14DVF)

1

3

7

13

17

22

Machine screw tightening

Screw tightening for soft

wood material

Screw tightening for hard

wood material

Thick screw tightening

When used as a drill.