Placing tool in service, Specifications – Ingersoll-Rand 115--EU User Manual

Page 3

3

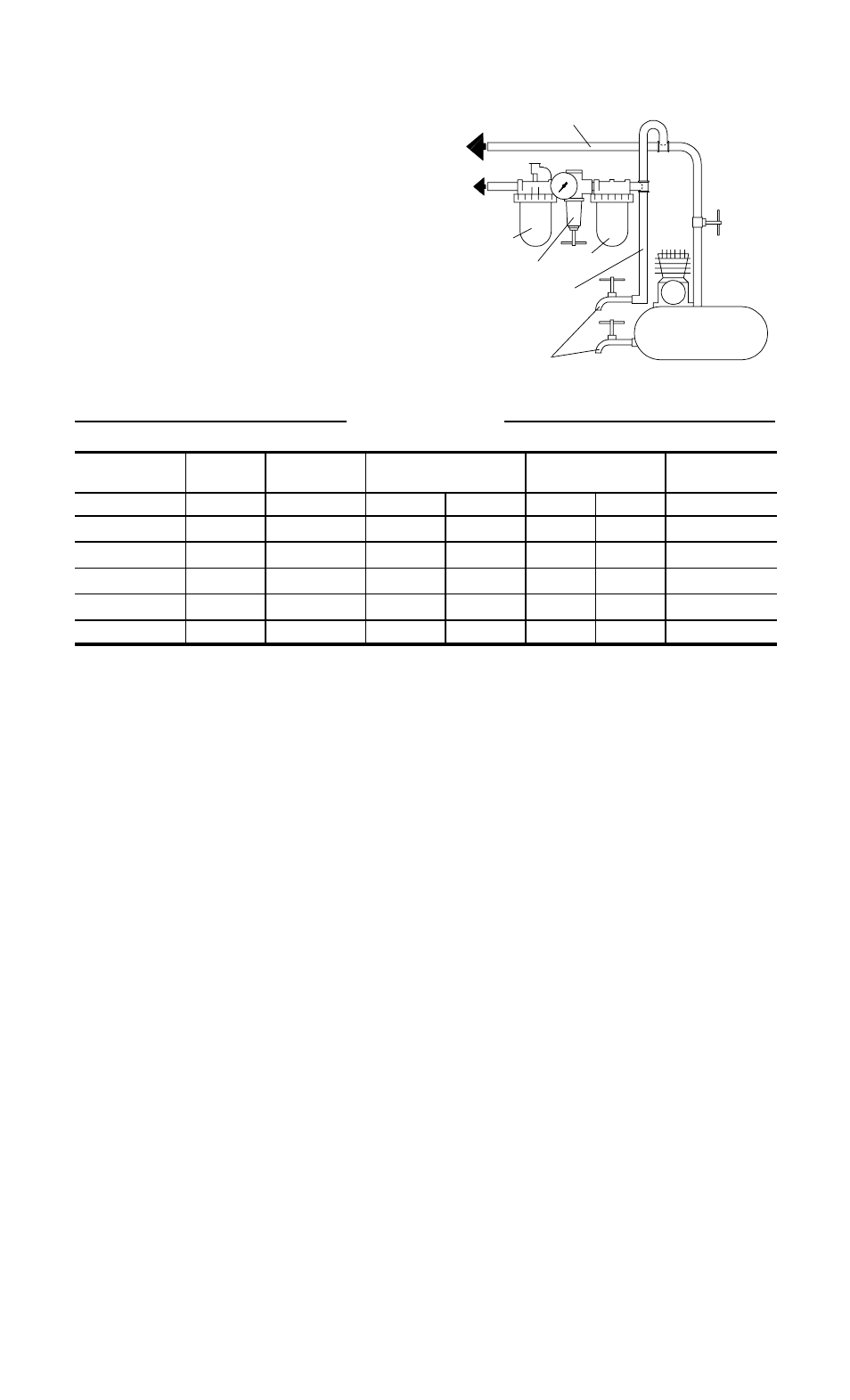

PLACING TOOL IN SERVICE

Never use a heavy oil or an oil that forms gum.

Either will clog the small parts, restrict valve motion

and cause loss of efficiency. If the operation of the

Hammer becomes sluggish, pour 3 cc of a clean, suitable

cleaning solution into the air inlet and operate the tool for

30 seconds. Lubricate in the regular manner immediately

after flushing.

MAIN LINES 3 TIMES

AIR TOOL INLET SIZE

TO

AIR

SYSTEM

TO

AIR

TOOL

LUBRICATOR

REGULATOR

FILTER

BRANCH LINE 2 TIMES

AIR TOOL INLET SIZE

DRAIN REGULARLY

COMPRESSOR

(Dwg. TPD905--1)

SPECIFICATIONS

Model

Type of

Handle

Impact/min.

Stroke Length

H

Sound Level

dB (A)

♦Vibrations

Level

in.

mm

Pressure

•Power

m/s

2

115, 115--EU

pistol grip

5 000

1--5/8

41

------

------

------

116, 116--EU

pistol grip

3 500

2--5/8

67

104.4

117.4

30.0

117, 117--EU

pistol grip

2 000

3--1/2

89

103.5

116.5

46.4

116H, 116H--EU

pistol grip

3 500

2--5/8

67

104.4

117.4

30.0

117H, 117H--EU

pistol grip

2 000

3--1/2

89

103.5

116.5

46.4

H

Tested in accordance with PNEUROP PN8NTC1.2 under load

♦ Tested in accordance with ISO8662--2

•

ISO3744