English, Housing the hexagonal bar wrench, Connecting with cleaner – InFocus CJ120VA User Manual

Page 29: Maintenance and inspection

28

English

HOUSING THE HEXAGONAL BAR WRENCH

It is possible to house the hexagonal bar wrench on the

base. (See Fig. 16)

CONNECTING WITH CLEANER

By connecting with cleaner (sold separately) through dust

collector and adapter (sold separately), most of dust can

be collected.

(1) Remove the hexagonal bar wrench from the base.

(2) Move the base fully forward. (Fig. 9, 10)

(3) Attach the chip cover with the shutter put between

the chip cover and gear cover. (Fig. 17)

(4) Connect the dust collector with adapter. (Fig. 18)

(5) Connect the adapter with the nose of cleaner. (Fig.

18)

(6) Insert dust collector into the rear hole or the base

until the hook catches in the notch. (Fig. 19)

(7) Press the hook to remove the dust collector.

MAINTENANCE AND INSPECTION

1. Inspecting the blade

Continued use of a dull or damaged blade will

result in reduced cutting efficiency and may cause

overloading of the motor. Replace the blade with

a new one as soon as excessive abrasion is noted.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool.

Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

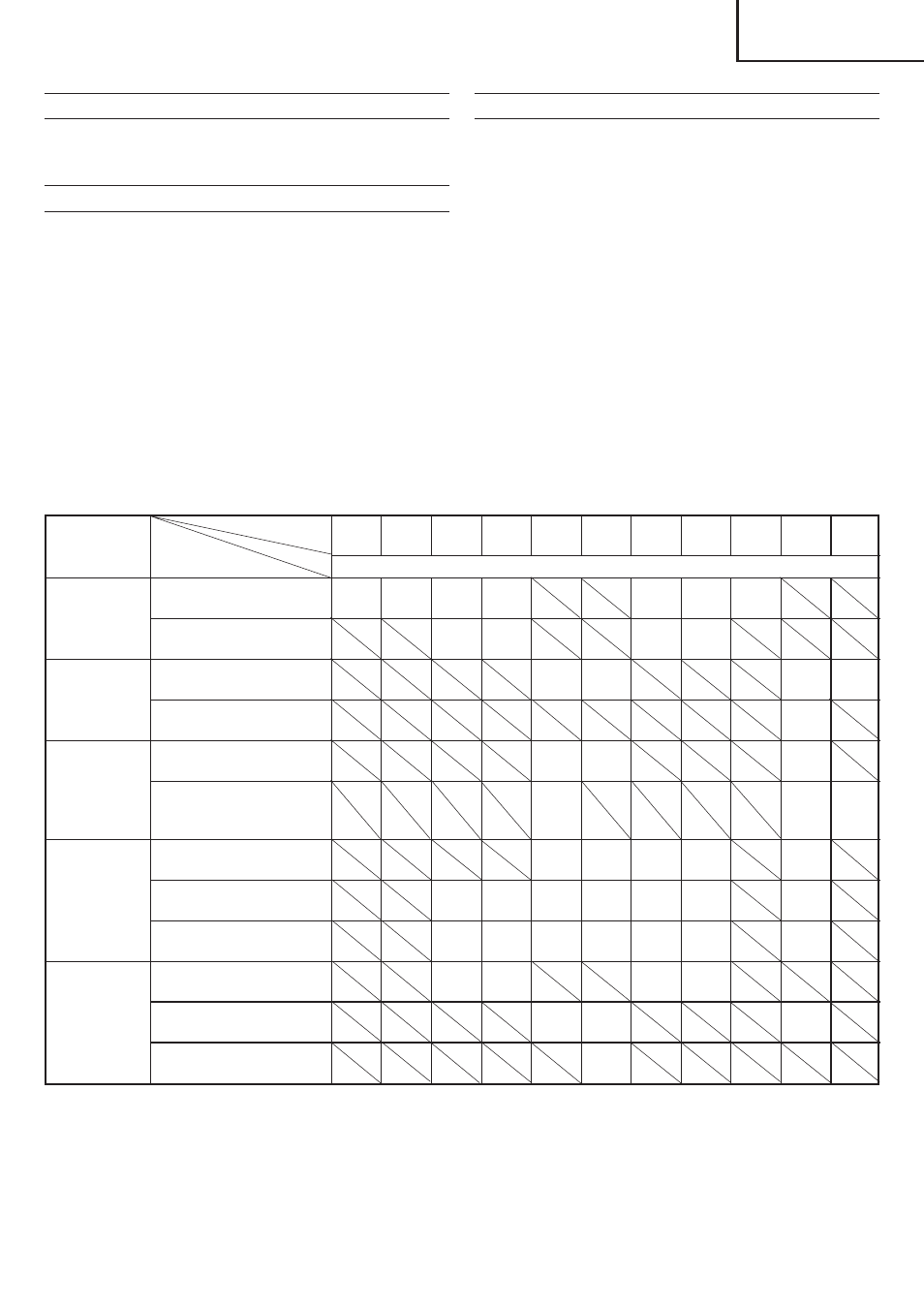

Table 1

List of appropriate blades

Material

Blade

No. 1

No. 1

No.11

No. 12,

No. 15

No. 16,

No. 21 No. 22 No. 41 No. 97

123X

to be cut

(Long)

(Super Long)

42

46

Material quality

Thickness of material (mm)

Lumber

General lumber

Below Below

10 ∼

Below

10 ∼

5 ∼

10 ∼

105

135

55

20

55

40

65

Plywood

5 ∼

Below

5 ∼

3 ∼

30

10

30

20

Iron plate

Mild steel plate

3 ∼

Below

2 ∼

1.5 ∼

6

3

5

10

Stainless steel plate

1.5 ∼

2.5

Nonferrous

Aluminium copper,

3 ∼

Below

Below

metal

brass

12

3

5

Aluminium sash

Height

Height Height

up to

up to

up to

25

25

30

Plastics

Phenol resin, melamin,

5 ∼

Below

5 ∼

Below

5 ∼

resin, etc.

20

6

15

6

15

Vinyl chloride,

5 ∼

Below

5 ∼

Below

5 ∼

3 ∼

5 ∼

acryl resin, etc.

30

10

20

5

30

20

15

Foamed polyethylene,

10 ∼

3 ∼

5 ∼

3 ∼

10 ∼

3 ∼

5 ∼

foamed styrol

55

25

25

25

55

40

25

Pulp

Card board,

10 ∼

3 ∼

10 ∼

3 ∼

corrugated paper

55

25

55

40

Hardboard

3 ∼

Below

3 ∼

25

6

25

Fiberboard

Below

6

NOTE:

⅜ The minimum cutting radius of No. 1 (Long), No.1 (Super Long), No. 21, No. 22 and No. 41 blades is 100 mm.

⅜ No. 1 (Long), No.1 (Super Long), No. 11, No. 12, No. 15, No. 16, No. 21, No. 22 and No. 97 blades are

sold separately.