English – InFocus WH14DM User Manual

Page 11

English

10

Fig. 18

MAINTENANCE AND INSPECTION

1. Inspecting the driver bit

Using a broken bit or one with a worn out tip is

dangerous because the bit can slip. Replace it.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so may result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool.

Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

4. Inspecting the carbon brushes (Fig. 14)

The motor employs carbon brushes which are

consumable parts. Since and excessively worn carbon

brush can result in motor trouble, replace the carbon

brush with new ones when it becomes worn to or

near the “wear limit”. In addition, always keep carbon

brushes clean and ensure that they slide freely within

the brush holders.

NOTE:

When replacing the carbon brush with a new one, be

sure to use the Hitachi Carbon Brush Code No. 999054.

5. Replacing carbon brushes

Take out the carbon brush by first removing the

brush cap and then hooking the protrusion of the

carbon brush with a slotted head screw driver, etc.,

as shown in Fig. 16.

When installing the carbon brush, choose the direction

so that the nail of the carbon brush agrees with the

contact portion outside the brush tube. Then push it

in with a finger as illustrated in Fig. 17. Lastly, install

the brush cap.

CAUTION:

Be absolutely sure to insert the nail of the carbon

brush into the contact portion outside the brush tube.

(You can insert whichever one of the two nails

provided.)

Caution must be exercised since any error in this

operation can result in the deformed nail of the carbon

brush and may cause motor trouble at an early stage.

6. Cleaning of the outside

When the impact driver is stained, wipe with a soft

dry cloth or a cloth moistened with soapy water. Do

not use chloric solvents, gasoline or paint thinner, as

they melt plastics.

7. Storage

Store the impact driver in a place in which the

temperature is less than 40°C, and out of reach of

children.

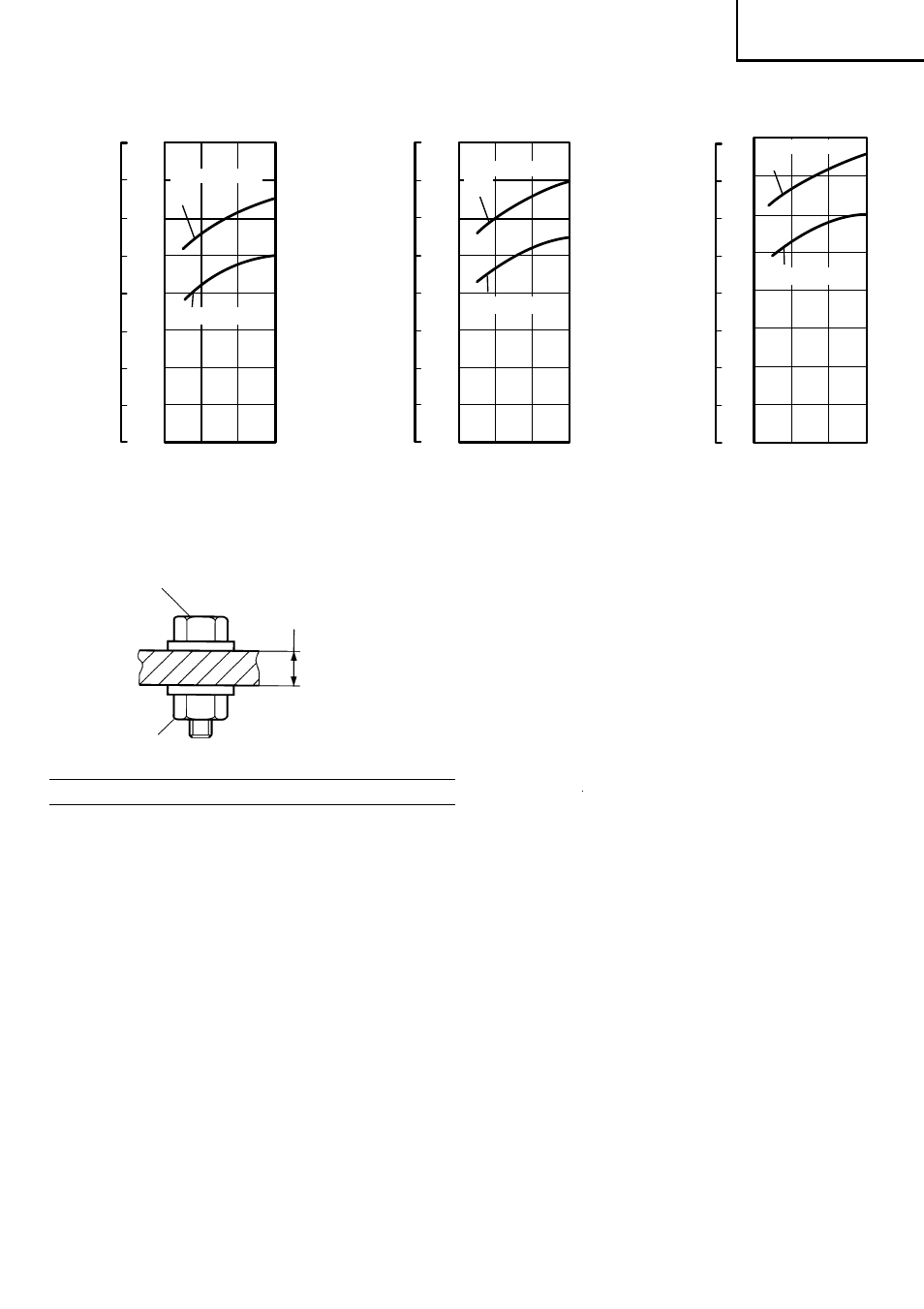

Nut

Fig. 19

*The following bolt is used.

Ordinary bolt: Strength grade 4.8

High tensile bolt: Strength grade 12.9

Bolt

Steel plate thickness t

Explanation of strength grade:

4 — Yield point of bolt: 32 kgf/mm

2

8 — Pulling strength of bolt: 40 kgf/mm

2

(

)

Tightening torque

Tightening torque

Tightening time: sec.

(Steel plate thickness

t = 10 mm)

Tightening time: sec.

(Steel plate thickness

t = 25 mm)

0

1

2

3

kgf•cm

1600

1400

1200

1000

800

600

400

200

0

N•m

160

140

120

100

80

60

40

20

0

kgf•cm

1600

1400

1200

1000

800

600

400

200

0

N•m

160

140

120

100

80

60

40

20

0

0

1

2

3

Ordinary bolt

Ordinary bolt

High tension

bolt

M10

×30

M12

×45

Tightening torque

Tightening time: sec.

(Steel plate thickness

t = 25 mm)

1600

1400

1200

1000

800

600

400

200

0

0

1

2

3

160

140

120

100

80

60

40

20

0

N•m

kgf•cm

Ordinary bolt

M14

×50

High tension

bolt

High tension

bolt