Milwaukee 6230N User Manual

Page 3

4

5

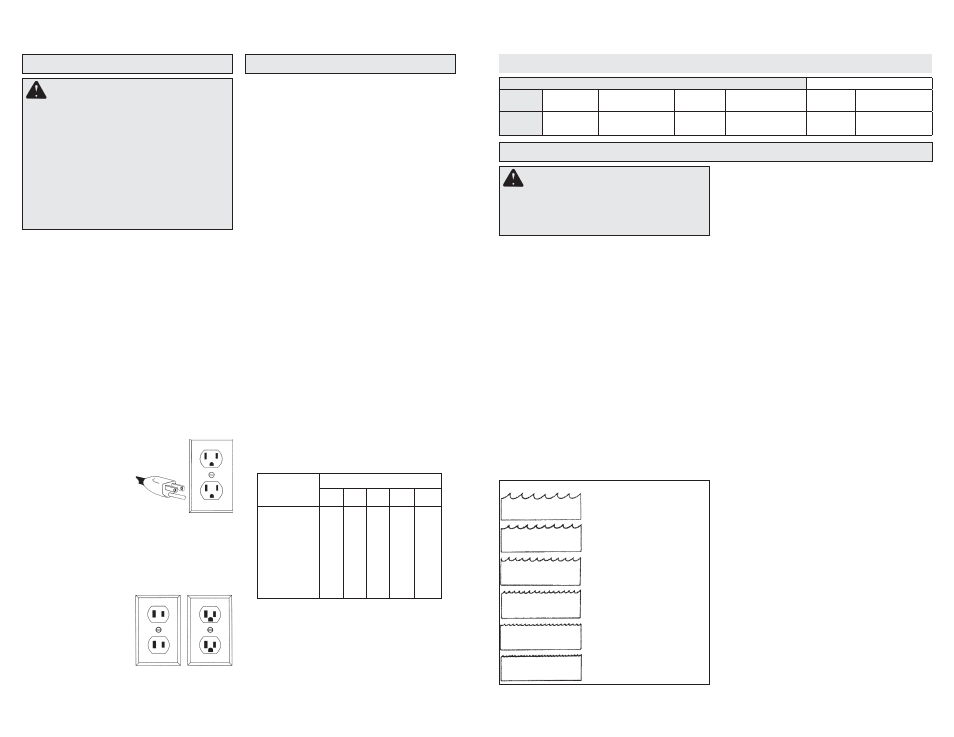

Grounded Tools:

Tools with Three Prong Plugs

Tools marked “Grounding Required” have a three

wire cord and three prong grounding plug. The

plug must be connected to a properly grounded

outlet (See Figure A). If the tool should electrically

malfunction or break down, grounding provides a

low resistance path to carry electricity away from

the user, reducing the risk of electric shock.

The grounding prong in the plug is connected

through the green wire inside the cord to the

grounding system in the tool. The green wire in the

cord must be the only wire connected to the tool's

grounding system and must never be attached to

an electrically “live” terminal.

Your tool must be plugged into an appropriate out-

let, properly installed and grounded in accordance

with all codes and ordinances.

The plug and outlet should

look like those in Figure A.

Double Insulated Tools:

Tools with Two Prong Plugs

Tools marked “Double Insulated” do not require

grounding. They have a special double insula-

tion system which satisfi es OSHA requirements

and complies with the applicable standards of

Underwriters Laboratories,

Inc., the Canadian Stan-

dard Association and the

National Electrical Code.

Double Insulated tools may

be used in either of the

120 volt outlets shown in

Figures B and C.

Fig. B

Fig. C

Fig. A

GROUNDING

WARNING

Improperly connecting the

grounding wire can result in the risk of elec-

tric shock. Check with a qualifi ed electrician

if you are in doubt as to whether the outlet is

properly grounded. Do not modify the plug

provided with the tool. Never remove the

grounding prong from the plug. Do not use

the tool if the cord or plug is damaged. If

damaged, have it repaired by a MILWAUKEE

service facility before use. If the plug will not

fi t the outlet, have a proper outlet installed by

a qualifi ed electrician.

Grounded tools require a three wire extension

cord. Double insulated tools can use either a two

or three wire extension cord. As the distance from

the supply outlet increases, you must use a heavier

gauge extension cord. Using extension cords with

inadequately sized wire causes a serious drop in

voltage, resulting in loss of power and possible tool

damage. Refer to the table shown to determine the

required minimum wire size.

The smaller the gauge number of the wire, the

greater the capacity of the cord. For example, a 14

gauge cord can carry a higher current than a 16

gauge cord. When using more than one extension

cord to make up the total length, be sure each cord

contains at least the minimum wire size required. If

you are using one extension cord for more than one

tool, add the nameplate amperes and use the sum

to determine the required minimum wire size.

Guidelines for Using Extension Cords

• If you are using an extension cord outdoors,

be sure it is marked with the suffi x “W-A” (“W”

in Canada) to indicate that it is acceptable for

outdoor use.

• Be sure your extension cord is properly wired

and in good electrical condition. Always replace

a damaged extension cord or have it repaired by

a qualifi ed person before using it.

• Protect your extension cords from sharp objects,

excessive heat and damp or wet areas.

READ AND SAVE ALL

INSTRUCTIONS FOR

FUTURE USE.

Recommended Minimum Wire Gauge

for Extension Cords*

Extension Cord Length

* Based on limiting the line voltage drop to

fi ve volts at 150% of the rated amperes.

Nameplate

Amperes

0 - 2.0

2.1 - 3.4

3.5 - 5.0

5.1 - 7.0

7.1 - 12.0

12.1 - 16.0

16.1 - 20.0

25'

18

18

18

18

16

14

12

75'

18

18

16

14

12

10

100'

18

16

14

12

10

150'

16

14

12

12

50'

18

18

18

16

14

12

10

EXTENSION CORDS

ASSEMBLY

WARNING

To reduce the risk of injury,

always unplug tool before attaching or remov-

ing accessories or making adjustments. Use

only specifi cally recommended accessories.

Others may be hazardous.

Specifi cations

Tool

Capacities

Cat. No.

Volts

Amps

FPM

Recommended

Blades

Round

Stock

Rectangular

Stock

6230N

6236N

120 AC

120 AC/DC

10.5

Lo 5.5 / Hi 10.5

0-420

320 / 420

Bi-Metal

Bi-Metal

4-3/4”

4-3/4”

4-3/4” x 4-3/4”

4-3/4” x 4-3/4”

Blades and Blade Selection

The blade dimensions required for the band saws

are: .020" thickness, 1/2" width and 44-7/8" in

length. The special .020" thickness reduces fl exure

fatigue and provides maximum tooth life. To maxi-

mize cutting life, use a blade with the correct pitch

(teeth per inch) for the specifi c cutting job.

Blades are available in several pitches. To select the

proper blade, three factors should be considered:

The size, shape, and type of material to be cut.

The following suggestions are for selecting the

right blade for various cutting operations. Keep in

mind that these are broad guidelines and that blade

requirements may vary depending upon the specifi c

size, shape and type of material to be cut. Gener-

ally, soft materials require coarse pitch blades and

hard materials require fi ne pitch blades. Use coarse

pitch blades for thick work and fi ne pitch blades for

thin work. It is important to keep at least three teeth

in the cut (see "Typical Application").

Changing Blades

1. UNPLUG THE TOOL BEFORE REMOVING OR

INSTALLING BLADES.

2. Turn the tension lock handle located on the front

of the saw 180° counterclockwise. This releases

the tension on the blade for easy removal.

3. Remove the blades from the pulley fi rst and then

from the guides.

4. To install a new blade, with the pulleys facing

up, insert the blade between the rollers and the

faces of the guides, making sure that the teeth

on the left side of the tool point towards the rear

of the tool.

5. With one hand, hold the blade in place between

the rollers and the guides and use the other hand

to position the blade around the pulleys. Be sure

that the blade lies freely within the guard channel

before starting the tool motor.

6. Turn the tension lock handle 180° clockwise to

lock the position. This will secure the blade on

the pulleys.

BE SURE THAT THE BLADE IS PROPERLY

SEATED ON THE PULLEYS BEFORE START-

ING THE CUT.

Adjusting the Work Steady Rest

To raise or lower the rest, loosen, but do not re-

move, the two adjusting screws. Slide the rest to the

desired position. Tighten the screws securely.

• For tough stock 1/2" to 3-3/8" in

diameter or width (available in

carbon steel only).

• For tough stock 3/8" to 1" in

diameter or width (available in

carbon steel only).

• For tough stock 3/16" up to

4-3/4" in diameter or width.

• For tough stock 5/32" to 3/4" in

diameter or width.

• For thin-wall tubing and thin

sheets heavier than 21 gauge.

• For thin-wall tubing and thin

sheets heavier than 21 gauge.

Fig. 1

6 Teeth per Inch

8 Teeth per Inch

10 Teeth per Inch

14 Teeth per Inch

18 Teeth per Inch

24 Teeth per Inch