Goodman Mfg AMV8 User Manual

Page 23

23

IO-247A

12/04

manifold pressure, use the following procedure.

1. Turn OFF gas to furnace at the manual gas shutoff valve

external to the furnace.

2. Connect a calibrated water manometer (or appropriate gas

pressure gauge) at the gas valve outlet pressure tap (refer

to gas valve figure in previous section).

3. Turn ON the gas supply and operate the furnace.

4. Measure gas manifold pressure with burners firing. Adjust

manifold pressure according to the table below:

Range

Nominal

Natural

Low Stage

1.6 - 2.2" w.c.

1.9" w.c.

High Stage

3.0 - 3.6" w.c.

3.5" w.c.

Propane

Low Stage

5.7 - 6.3" w.c.

6.0" w.c.

High Stage

9.7 - 10.3" w.c.

10.0" w.c.

Manifold Gas Pressure

Gas

The final manifold pressure must not vary more than ± 0.3 “ w.c.

from the above specified pressures. Any necessary major changes

in gas flow rate should be made by changing the size of the burner

orifice.

5. To adjust the gas valve pressure regulator, remove the

regulator cap

6. Turn the adjustment screw clockwise to increase the

pressure, or counterclockwise to decrease the pressure.

7. Securely replace the regulator cap.

8. Turn OFF gas to furnace at the manual shutoff valve and

disconnect manometer.

9. Reinstall gas valve outlet pressure tap plug before turning

on gas to furnace.

G

AS

I

NPUT

R

ATE

M

EASUREMENT

(N

ATURAL

G

AS

O

NLY

)

The gas input rate to the furnace must never be greater than that

specified on the unit rating plate. To measure natural gas input

using the gas meter, use the following procedure.

1. Turn OFF the gas supply to all other gas-burning appliances

except the furnace.

2. While the furnace is operating, time and record one complete

revolution of the smallest gas meter dial.

3. Calculate the number of seconds per cubic foot (sec/ ft

3

) of

gas being delivered to the furnace. If the dial is a one cubic

foot dial, divide the number of seconds recorded in step 2

by one. If the dial is a two cubic foot dial, divide the number

of seconds recorded in step 2 by two.

4. Calculate the furnace input in BTUs per hour (BTU/ hr). Input

equals the sum of the installation’s gas heating value and a

conversion factor (hours to seconds) divided by the number

of seconds per cubic foot. The measured input must not be

greater than the input indicated on the unit rating plate.

EXAMPLE:

Installation’s gas heating (HTG) value: 1,000 BTU/ft

3

(Obtained from gas supplier)

Installation’s seconds per cubic foot: 34 sec/ ft

3

Conversion Factor (hours to seconds): 3600 sec/hr

Input = (Htg. value x 3600) ÷ seconds per cubic foot

Input = (1,000 BTU/ft

3

x 3600 sec/hr) ÷ 34 sec/ ft

3

Input = 106,000 BTU/hr

This measured input must not be greater than the input

indicated on the unit rating plate.

gas piping drip leg. The supply pressure must be measured with

the burners operating. To measure the gas supply pressure, use

the following procedure.

With Power and Gas Off:

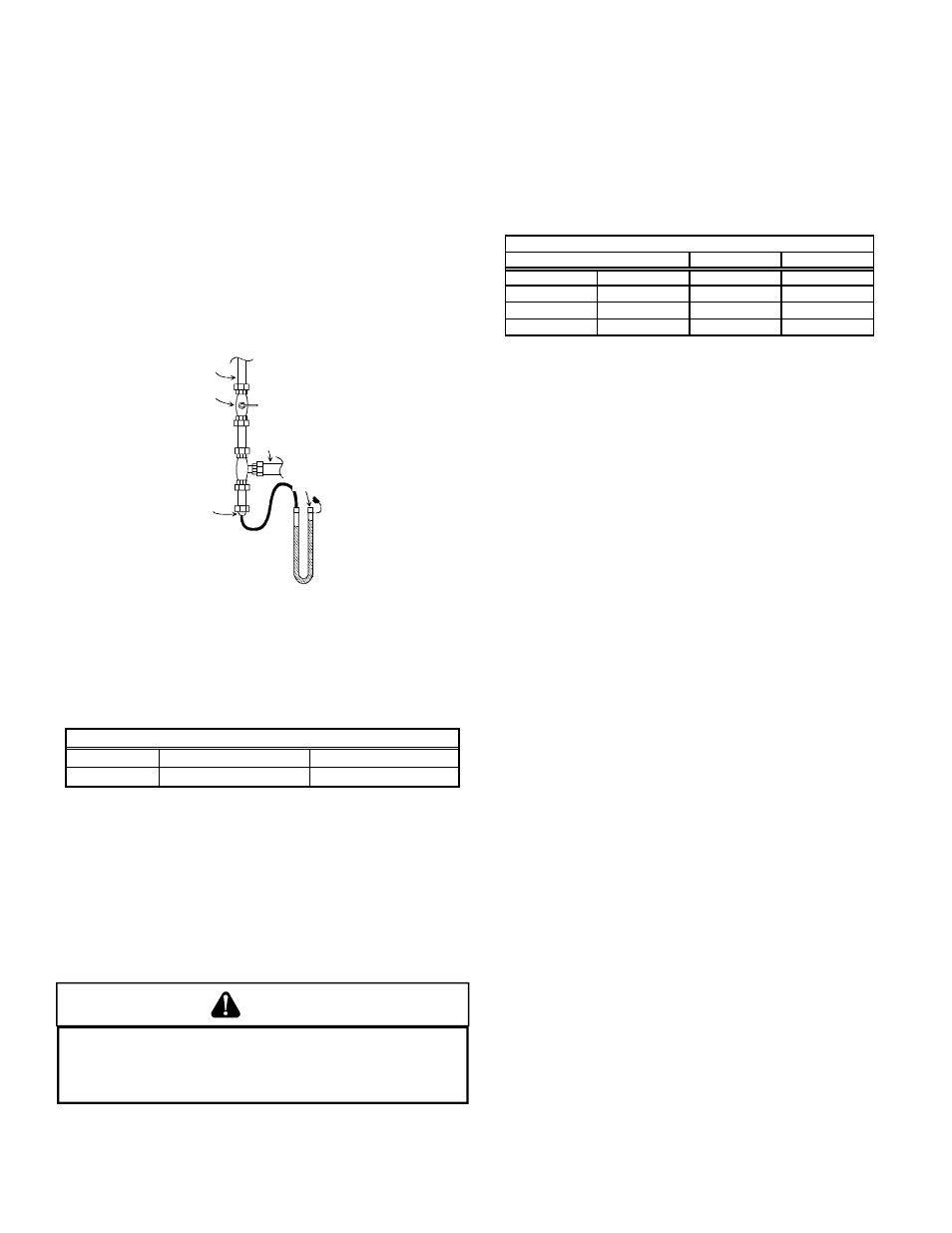

1. Connect a water manometer or adequate gauge to the “inlet

pressure tap” of the gas valve.

As an alternative method, inlet gas pressure can also be

measured by removing the cap from the drip leg and

installing a predrilled cap with a hose fitting (Figure 26).

With Power and Gas On:

2. Put furnace into heating cycle and turn on all other gas

consuming appliances.

If operating pressures differ from the Inlet Gas Supply Pressure

table below, make necessary pressure regulator adjustments, check

piping size, etc., and/or consult with local utility.

Gas Line

Gas

Shutoff

Valve

Gas Line

To Furnace

Drip Leg Cap

With Fitting

Manometer Hose

Manometer

Open To

Atmosphere

Measuring Inlet Gas Pressure (Alternate Method)

3. Turn ON the gas supply and operate the furnace and all

other gas consuming appliances on the same gas supply

line.

4. Measure furnace gas supply pressure with burners firing.

Supply pressure must be within the range specified in the

table below.

Natural Gas

Minimum: 5.0" w.c.

Maximum:10.0" w.c.

Propane Gas

Minimum: 11.0" w.c.

Maximum:13.0" w.c.

Inlet Gas Supply Pressure

If supply pressure differs from table, make the necessary

adjustments to pressure regulator, gas piping size, etc., and/or

consult with local gas utility.

5. Turn OFF gas to furnace at the manual shutoff valve and

disconnect manometer. Reinstall plug before turning on

gas to furnace.

6. Turn OFF any unnecessary gas appliances stated in step

3.

G

AS

M

ANIFOLD

P

RESSURE

M

EASUREMENT

AND

A

DJUSTMENT

CAUTION

T

O PREVENT UNRELIABLE OPERATION OR EQUIPMENT DAMAGE, THE GAS

MANIFOLD PRESSURE MUST BE AS SPECIFIED ON THE UNIT RATING PLATE.

O

NLY MINOR ADJUSTMENTS SHOULD BE MADE BY ADJUSTING THE GAS VALVE

PRESSURE REGULATOR.

Only small variations in gas pressure should be made by adjusting

the gas valve pressure regulator. The manifold pressure must be

measured with the burners operating. To measure and adjust the