Building automation system (bas) configuration – Honeywell Local Operator Interface S7999B User Manual

Page 6

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

65-0303—05

6

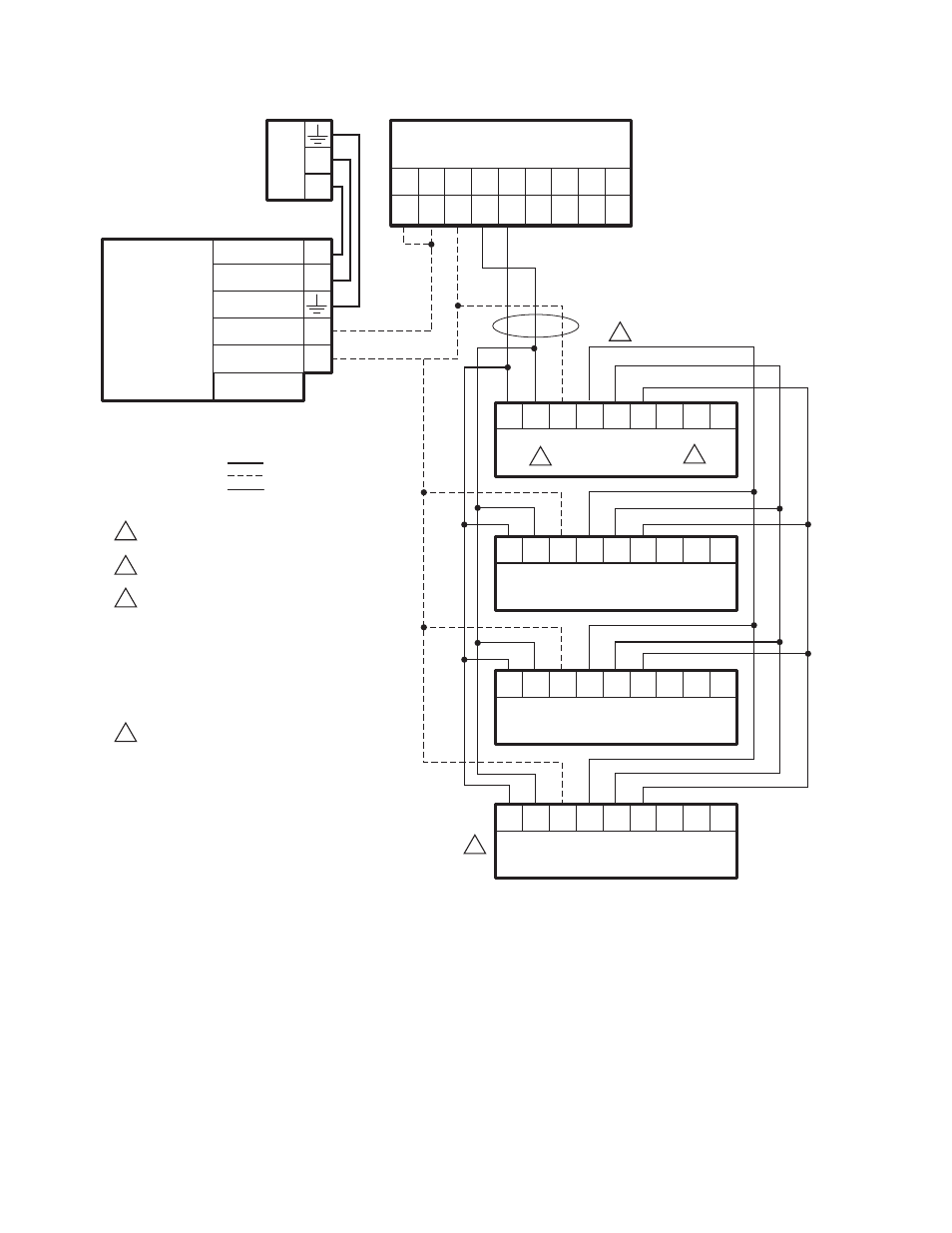

Fig. 4. S7999B wiring diagram for lead lag.

BUILDING AUTOMATION

SYSTEM (BAS)

CONFIGURATION

Connect the BAS Modbus wiring to COM2 of the S7999B as

shown in Fig. 5.

Ensure all S7999B devices have unique Modbus addresses as

defined in Fig. 5.

M32005

2

1

4

5

6

7

8

9

3

+12

(B)

(A)

N/C

GND

(C)

+12

N/C

(A)

(B)

S7999B

AS SYSTEM DISPLAY

COM1

COM2

L1

L2

120

VAC

VADJ

V+

N

L

V-

DC OUT

(COMMON GND)

12 DC OUT +

EARTH

GROUND

120VAC (L1)

NEUTRAL (L2)

MEAN WELL S-25-12

DO NOT CONNECT THE S7999B TO TERMINALS 1 2 3.

THIS WILL RENDER THE DISPLAY INOPERABLE.

DISPLAY CAN ALSO BE CONNECTED TO MB2; A, B, C

AND THE SOLA SLAVES NEED TO BE WIRED TO MB1.

CONTROLLER HAS TWO AVAILABLE MODBUS

CONNECTIONS: THIS CONFIGURATION REQUIRES ONE

FOR CONTROL LEAD LAG COMMUNICATION AND ONE

FOR A S7999B SYSTEM DISPLAY.

THERE IS NOT A CONNECTION AVAILABLE FOR A

LOCAL TOUCHSCREEN DISPLAY (S7999C).

THE ECOM CONNECTION IS AVAILABLE FOR

CONNECTIONS OF A LOCAL KEYBOARD

DISPLAY MODULE.

UP TO A MAXIMUM OF 8 SOLA SLAVES IN A

LEAD LAG NETWORK.

POWER SUPPLY

WIRING KEY

LOW VOLTAGE

DATA

LINE VOLTAGE

SOLA LL MASTER

AND SLAVE 1

2

3

C

B

A

C

B

A

1

J3

MB1

ECOM

MB2

2

3

C

B

A

C

B

A

1

SOLA SLAVE 2

J3

MB1

ECOM

MB2

2

3

C

B

A

C

B

A

1

SOLA SLAVE 3

J3

MB1

ECOM

MB2

2

3

C

B

A

C

B

A

1

SOLA SLAVE 4

J3

MB1

ECOM

MB2

1

1

2

3

3

4

4

2