Vacuum chamber seals, Cooling fan, Vacuum packaging guidelines – Weston Harvest Guar Portable Vacuum Sealer User Manual

Page 6

-6-

-19-

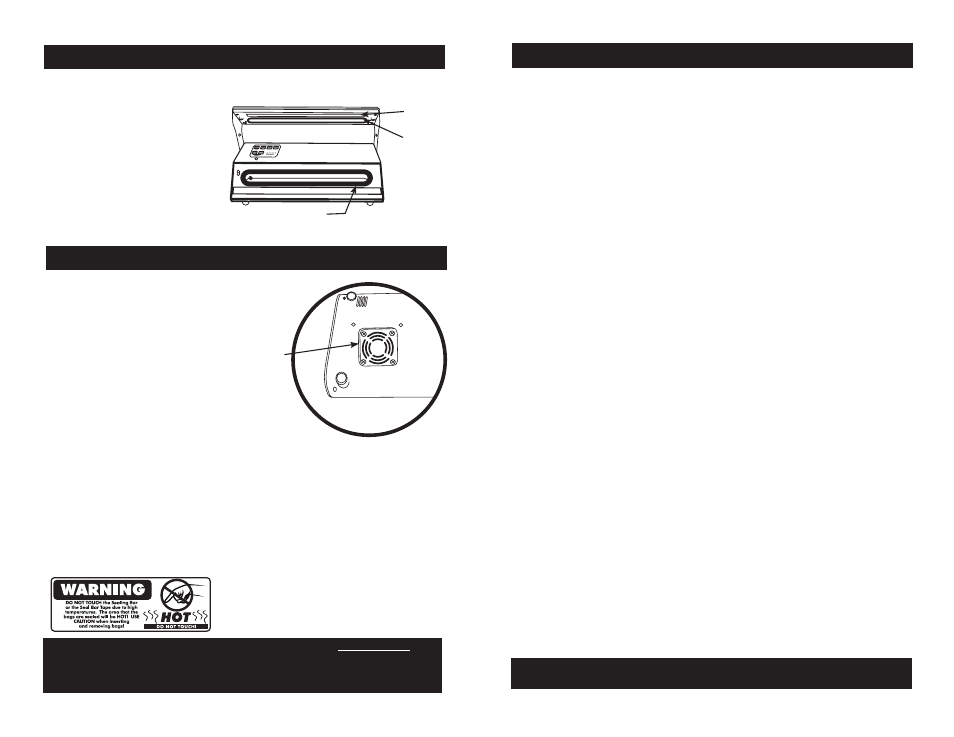

VACUUM CHAMBER SEALS

The

Vacuum Chamber Seal

may wear over time and require

replacement. See the “Service

Instructions” section of this manual

for information on replacing

the

Vacuum Chamber Seal, if

necessary (Figure 2).

COOLING FAN

The

Vacuum Sealer has an Internal

Cooling Fan that runs whenever the

unit is plugged in and turned on. To

save energy, turn the unit “OFF” and

unplug the

Power Cord when not in

use.

Do not block the

Fan Vent (Figure

3)

on the bottom of the Vacuum

Sealer. Keep the area clear to allow

for proper air circulation.

Cooling

Fan Vent

BOTTOM OF

VACUUM SEALER

Vacuum

Chamber

Lid Seal

Seal Bar

Insulator

Vacuum Chamber Seal

Figure 2

Figure 3

Very Moist Foods: It is best to freeze very moist food items, like fish, before vacuum

sealing them. The excessive moisture can interfere with the

Sealing Bar’s ability to

completely fuse the layers of the bag together.

Powdery Items: When vacuum sealing powdery items, like flour, it is best to keep

them in their original packaging before putting them into the vacuum bags. The fine

powder may get sucked into the

Vacuum Pump and cause enough damage to shorten

the life of your

Vacuum Sealer. Powdery items may also interfere with the bag sealing

function.

Sharp or Pointed Items: When vacuum sealing sharp or pointy items, it is best to

cushion the edges so they do not puncture the bag during the vacuum process.

YEAST & BACTERIA

For best results in extending the life of foods, it is important to vacuum package foods

that are fresh. Once food has begun to deteriorate, vacuum packaging may only slow

the deterioration process. Vacuum sealing cannot completely prevent the growth of

mold. Other disease causing microorganisms can still grow in low oxygen environments

and may require further measures to be eliminated.

Yeast: The development of yeast can be slowed by refrigeration and completely

stopped by freezing food at 0

o

F (-18

o

C). Yeast causes fermentation, which will give food

an identifiable smell.

Bacteria: Freezing cannot eliminate bacteria, but their growth can be stopped. The

growth of bacteria can be easily identified by an offensive odor and sometimes a slimy

texture. Some bacteria, like the one that causes botulism, can grow in low oxygen

environments and cannot be detected by smell, taste or color. Be sure that all foods are

stored and cooked properly before eating.

COOKING & HEATING

.

Before microwaving vacuum-packed foods, puncture or open the bag to allow hot air

to escape while heating.

.

Vacuum-packed foods can be thawed or cooked in boiling water.

.

Vacuum-packed perishable foods like meats, vegetables and cheeses must

be refrigerated (at or below 34

o

F (1.1

o

C)) or frozen, especially acid-free or low-acid foods.

VACUUM PACKAGING GUIDELINES

CAUTION! It is important to follow the “Food Safety” guidelines. For the most

up to date instruction visit the USDA website.

NOTE: The Vacuum Sealer is ONLY intended to be used with VACUUM BAGS. For

best results, only use the recommended vacuum bags with an embossed or mesh lining.

DO NOT USE HOUSEHOLD BAGS! Any other uses of the Vacuum Sealer, other

than the uses described in this booklet, could potentially damage the appliance and void

the warranty!