Troubleshooting chart – Winco 2FS Generators 2000 Watt Belt Drive User Manual

Page 9

9

2095-0

60706-230

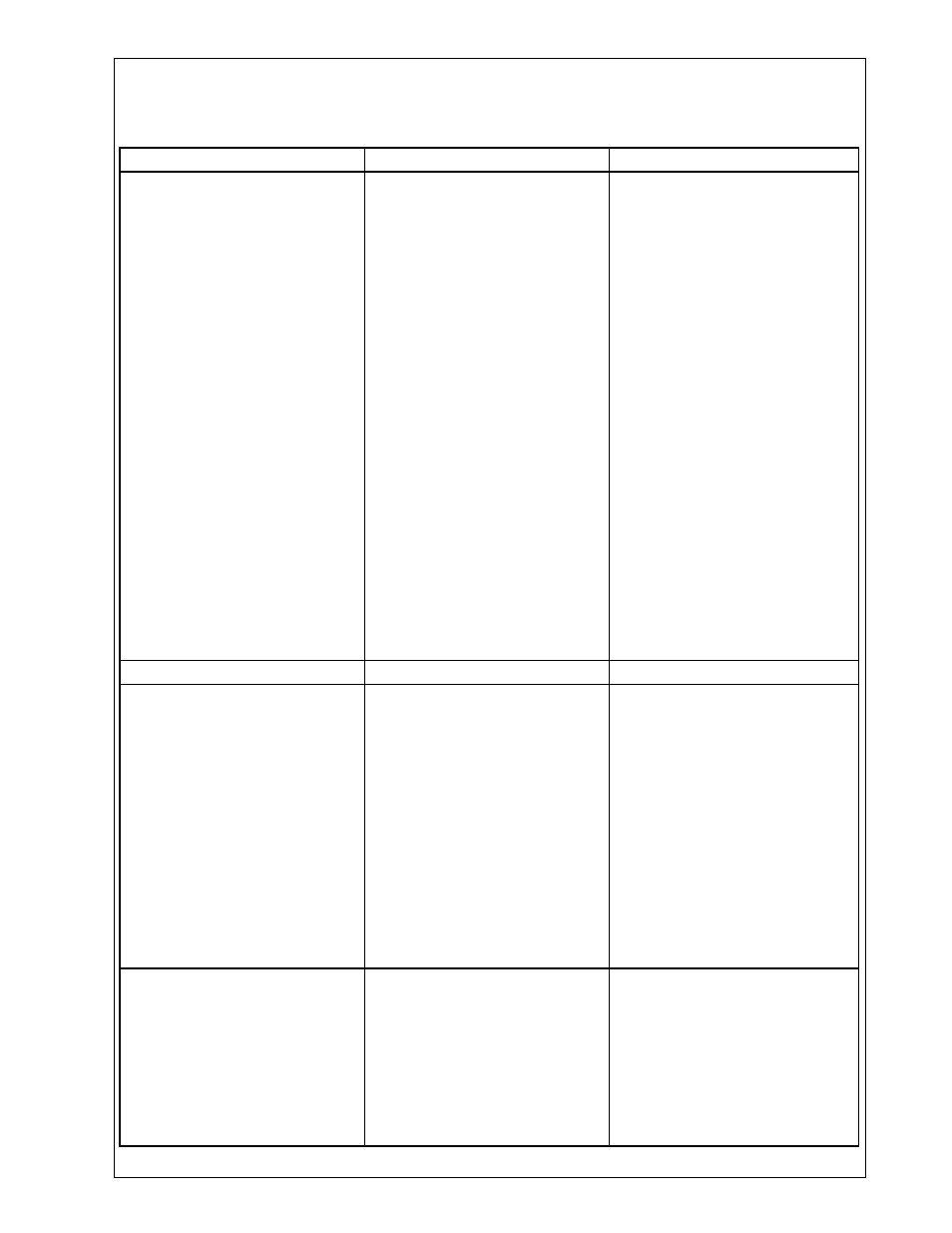

SYMPTOM

POSSIBLE CAUSE(S)

CORRECTIVE ACTION

No output or low voltage.

. Open or shorted armature.

2. Open or grounded field coil(s).

3. Generator operating below

correct RPM speed.

4. Generator overloaded.

5. Short circuit in the load.

6. Loose (or broken) wires or

connections in the control box.

7. Defective rectifier.

8. Dirty slip rings.

9. Brushes binding in holders.

0. Loss of residual magnetism.

. Replace armature.

2. Replace field coil(s).

3. Generator must be operated at

3600 RPM +/- 90 RPM for proper

output voltage.

4. Reduce load to generator

nameplate.

5. Disconnect the load. Check

motors, appliances and load leads

for short circuits. Repair short.

6. Remove panel cover and

check all wiring and connections.

Tighten and/or repair where nec-

essary.

7. Test rectifier. Replace if defec-

tive.

8. Clean and polish. Use 00

sandpaper and crocus cloth,

never emery paper.

9. Check brushes for swelling.

Replace defective brushes. Clean

brush holders.

0. Check output voltage with

sensitive meter. If very low (i.e.

1/2 volt) flash fields with a 12 VDC

battery.

Output voltage too high.

Engine speed too high.

See engine manual.

Generator overheating.

. Generator overloaded.

2. Armature rubbing pole shoes.

3. Poor ventilation.

4. Short circuit in fields.

5. Short turns in armature.

. Reduce load.

2. Check bearing condition.

Check field shell bearing bracket

alignment.

3. Clear inlet and outlet air vents

of debris. If unit is housed, ensure

at least 2 ft. clearance on all sides

and that inlet and outlet vents are

of adequate size.

4. Repair or replace - open or

shorted fields should be replaced.

Grounded fields may be repaired

by insulating at the point where

the ground occurs.

5. Replace armature.

Sparking at the brushes.

. Generator overloaded.

2. Brushes not seated properly.

3. Slip rings rough or eccentric.

4. Brushes sticking in brush

holder.

5. Brushes worn down shorter

than 3/8 inch.

. Reduce load.

2. Contour brushes (see maint.).

3. Redress slip rings (see maint.).

4. Remove brushes and inspect

and correct problem.

5. Replace brush. NOTE: Al-

ways replace brushes a full set at

a time.

TROUBLESHOOTING CHART