Winco 2FS Generators 2000 Watt Belt Drive User Manual

Page 7

7

2095-0

60706-230

MAINTENANCE

GENERAL

The main components of the generator are: field

frame, field coils, armature, brushes. brush holder

assembly, brackets, armature, and generator cooling

fan.

BRUSHES

Under ordinary circumstances brushes will operate

for thousands of hours without requiring replace-

ment. They should be inspected after the first

000 hours of operation, and after every 500 hours

of operation thereafter. Remove brushes one at

a time and check for length. Be sure that each

moves freely in the brush holder. Brushes should be

replaced when worn down to 3/8”. Always replace

brushes in complete sets, never singularly. When

replacing brushes be careful to reconnect the lead

wire properly. Poor contact or “skipping” between

brush and slip ring can be caused by oil and grit,

flint, or other hard contaminant substances on the

brushes, or by the brush not being properly shaped

to fit the slip rings.

Remedy these defects by cleaning the rings and

brushes and then fitting the brushes to the slip ring

curvature. Place #00 sandpaper under the brushes

with the abrasive side to the brushes, and work it

back and forth until the brushes are the same shape

as the slip rings.

SLIP RINGS

The continuous copper rings located at the end of

armature are the power collector rings or ‘slip rings’.

For proper generator output, the surface of these slip

rings must have a highly polished finish. Under sus-

tained use, it is advisable to check and occasionally

polish ring surfaces with a crocus cloth to maintain

the finish under normal conditions. This should not

be required more than once each thousand hours of

operation.

ELECTRICAL TESTING

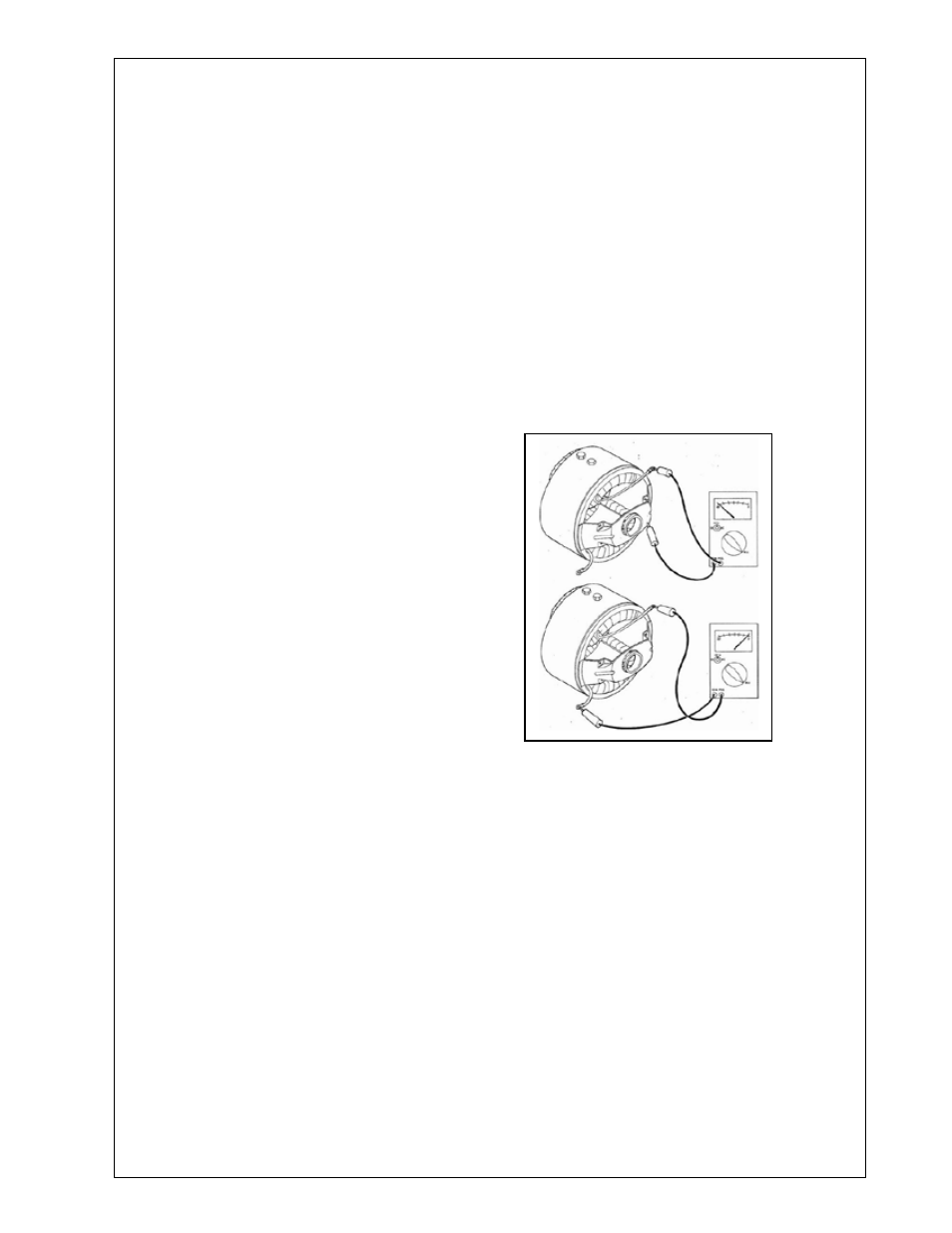

TESTING COILS FOR OPENS AND GROUNDS

1. Disconnect field leads from rectifier.

2. Set multi-meter to read resistance, and connect

the meter leads to the field leads. If field is open,

meter will read infinite resistance (very high ohms),

repair or replace field if it is open. Typical resistance

for these fields varies from 12.8 to 14.1 ohms.

3. Leaving one meter lead connected to the field,

connect the other meter lead to the field shell. If

meter indicates continuity (any reading - should be

infinite resistance), the field is grounded and should

be repaired or replaced. To determine which of the

fields is grounded, cut the connector between the

two coils and retest to determine which coil has the

low resistance path.