Operating instructions – Carbolite PTC 12/20/150 User Manual

Page 4

PTC

4

MF11 – 3.08

3.0 O

PERATING

I

NSTRUCTIONS

3.1 Operating Cycle

The furnace is fitted with an instrument switch. The switch cuts off power to the controller.

Connect the furnace to the electrical supply.

Operate the instrument switch to activate the temperature controller. The controller becomes

illuminated and goes through a short test cycle. Set the temperature as required - see section 4.0.

As the furnace heats up the Heat light glows steadily at first and then flashes as the furnace

approaches the desired temperature. For further information on temperature control see section 4.0.

To turn the furnace off, set the Instrument switch to it’s off position; the controller display will go

blank. If the furnace is to be left off unattended, isolate it the electrical supply.

3.2 General Operating Notes

Heating element life is shortened by use at temperatures close to maximum. Do not leave the

furnace at high temperature when not required. The maximum temperature is given on the furnace

rating label and on the back page of this manual.

Light weight ceramic fibre insulation can easily be marked by accidental contact. Some fine cracks

may be visible on the surface of the insulation, or may develop in the surface of the chamber due

to the progressive shrinkage of the insulation materials. Cracks are not usually detrimental to the

functioning or the safety of the furnace.

3.3 Operator Safety

Ceramic materials used in furnace manufacture become electrically conducting at high

temperature.

The furnace incorporates a Heater Switch on the control panel which safely interrupts the heating

element circuit. Use this switch when inserting anything into the furnace chamber which might

touch the interior. Do not rely upon the instrument switch for this purpose.

3.4 Instructions for Use as a Calibration Furnace

The PTC 12/20/150 is designed for calibration by the comparison method, which consists of

comparing the thermocouple under test with a reference thermocouple. This reference

thermocouple can have traceability to national standards, either if it is ordered with this

requirement, or by getting it independently calibrated.

In the PTC 12/20/150 the reference thermocouple is built in and has its own indicator marked

Reference Temperature. It is located within the work tube such that its tip is positioned close to

that of the thermocouple to be tested in the part of the tube which has the most uniform

temperature.

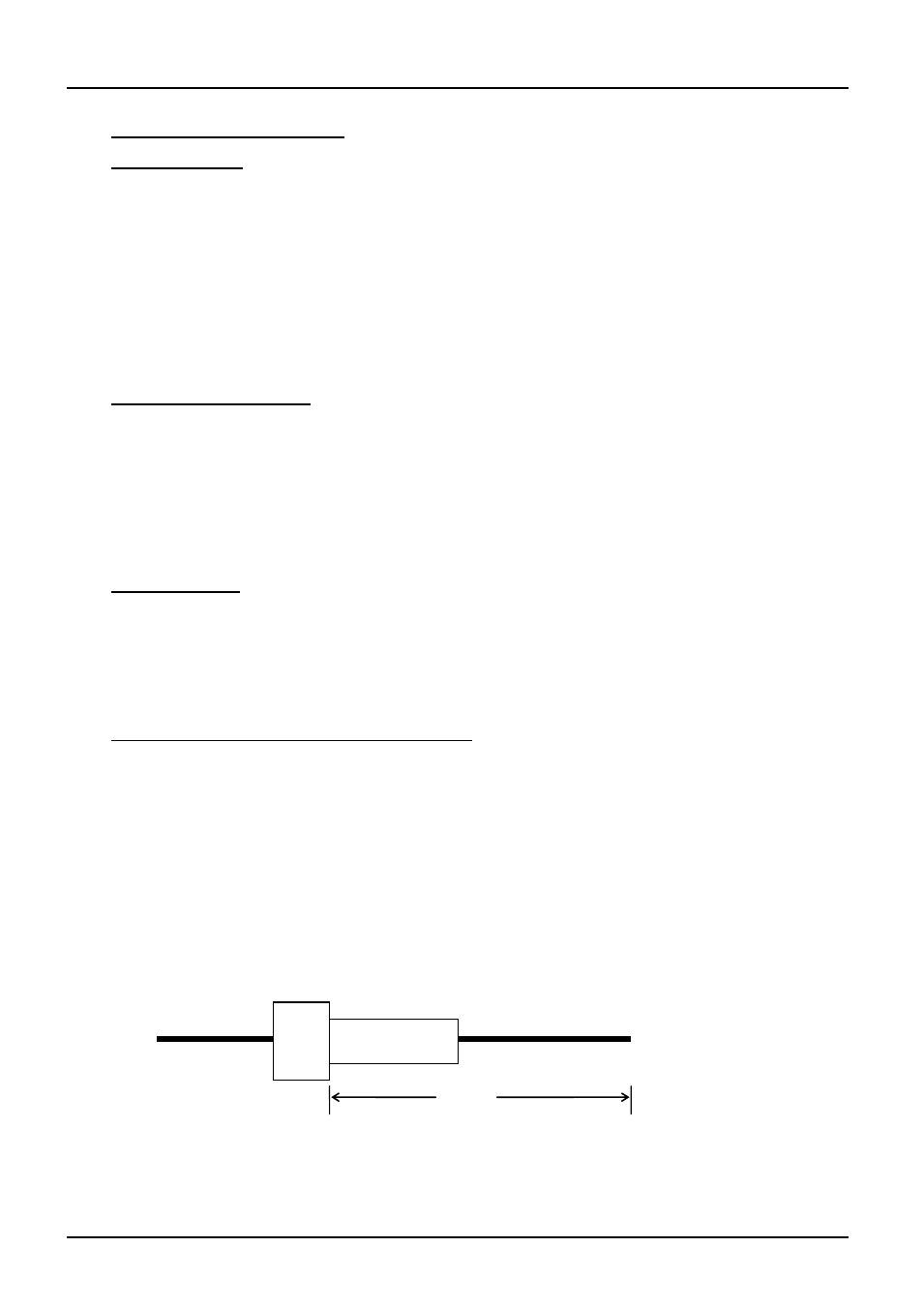

The thermocouple to be calibrated should be passed through an end plug with a suitable size hole,

with the tip 120 to 130mm from the step in the plug.

If thermocouples with different outer diameters are to be calibrated then end plugs with different

size holes should be used. These may be ordered from Carbolite. The maximum recommended

125mm

thermocouple

tip