Warner Electric ECN-24280 10_18_11 OBSOLETE User Manual

Page 2

2

Warner Electric • 800-825-9050

P-1374 • 819-0075

Replacement Compressor Clutch for

Chrysler Automobiles

This compressor clutch has been developed

specifically for automobile air conditioning

applications. Properly installed, it will provide

maintenance free service. The clutch, using a

stationary field principle, DOES NOT REQUIRE

SLIP RINGS OR BRUSHES.

The clutch consists of two major components,

a stationary magnet field assembly and a

rotor-pulley assembly. The field assembly is

mounted on the compressor. The rotor-pulley

assembly is mounted to the compressor

crankshaft and driven by V-belts from the engine

crankshaft pulley. Electricity energizes the clutch

field to couple the clutch magnetically, thus

driving the compressor. De-energizing the clutch

uncouples the compressor.

Service

This compressor clutch automatically

compensates for wear requiring no adjustment

throughout the life of the clutch. Do not

lubricate the unit. If the clutch should fail to

operate, check the electrical circuit to be sure

that the proper voltage is being supplied to the

clutch. Do not attempt to make any mechanical

adjustments on the clutch.

Diagnose Clutch Failure

Most compressor clutch failures are a direct

result of an A/C system problem or failure.

Before installing a new clutch, determine what

caused the old clutch to fail and fix the system

problem. By simply replacing the clutch without

fixing the cause of the clutch failure, the new

clutch may fail in the same manner as the old

clutch. Please refer to the Warner Electric “Air

Conditioning Clutch Trouble Shooting Guide”

and the appropriate manufacturer’s A/C Service

Manuals.

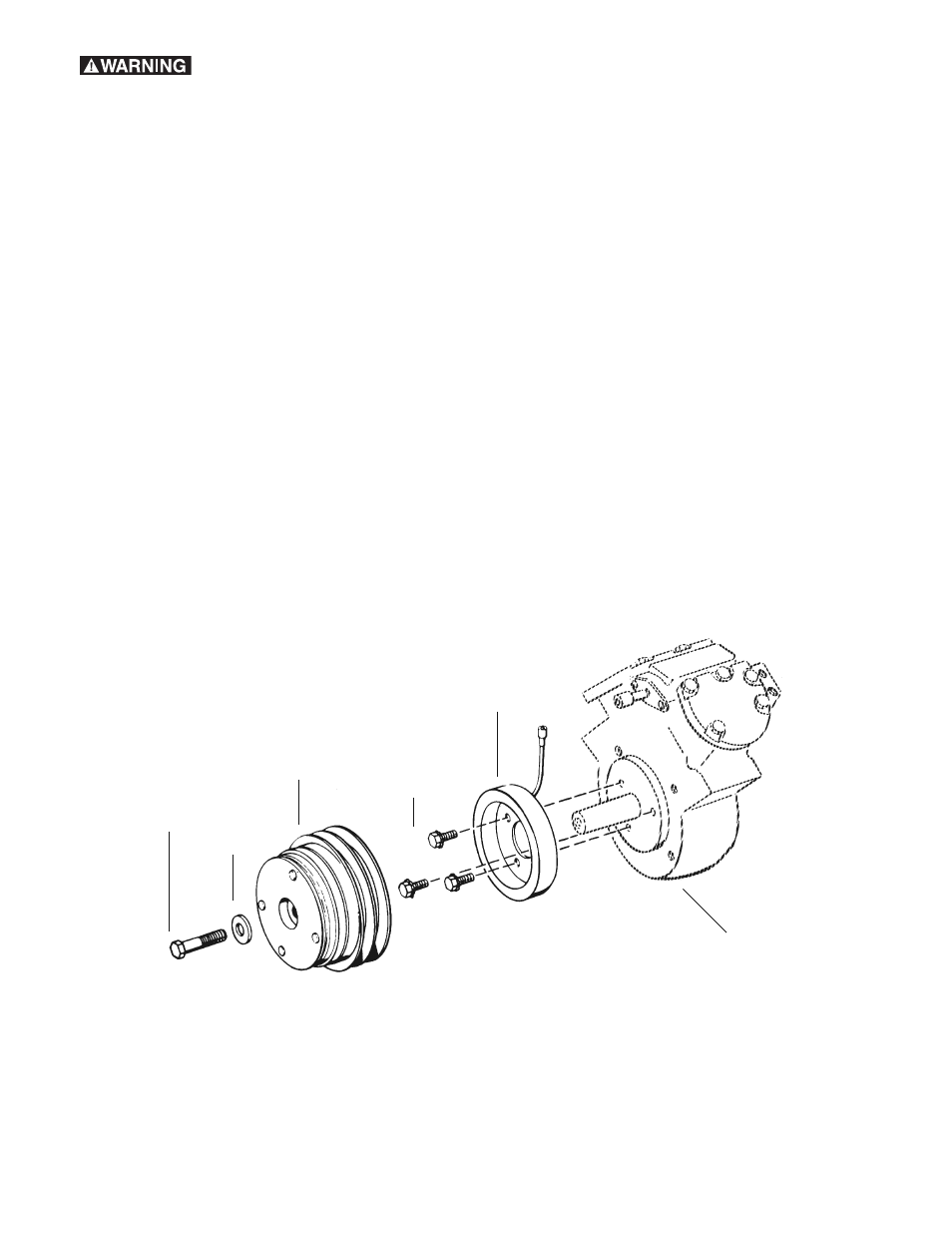

Installation

2

Rotor

Pulley

Assembly

1

Field

Assembly

Compressor

4

Washer

3

Capscrews

and

Lockwashers

5

Capscrew

Failure to follow these

instructions may result in product damage,

equipment damage, and serious or fatal injury

to personnel.