Warner Electric H 110 VAR00 User Manual

Page 4

4 Warner Electric Europe • +33 (0)2 41 21 24 24

P-2066-WE • 2/13

4

Maintenance

4.1

Maintenance

When operating conditions are complied with (running in oil, oil temperature, rotation speed, etc) the wear on

the H110 disc set is found to be negligible, in addition, it is automatically compensated for, until all the wear

adjustment available is used up, by movement of the piston. So this type of clutch needs little maintenance.

It is however necessary to:

•

Change the oil after 40 h running from first use, then every year of normal running

•

Regularly check the pressure chamber seal and in the event of leakage, or after 5 years use, change the

seals (701, 702)

•

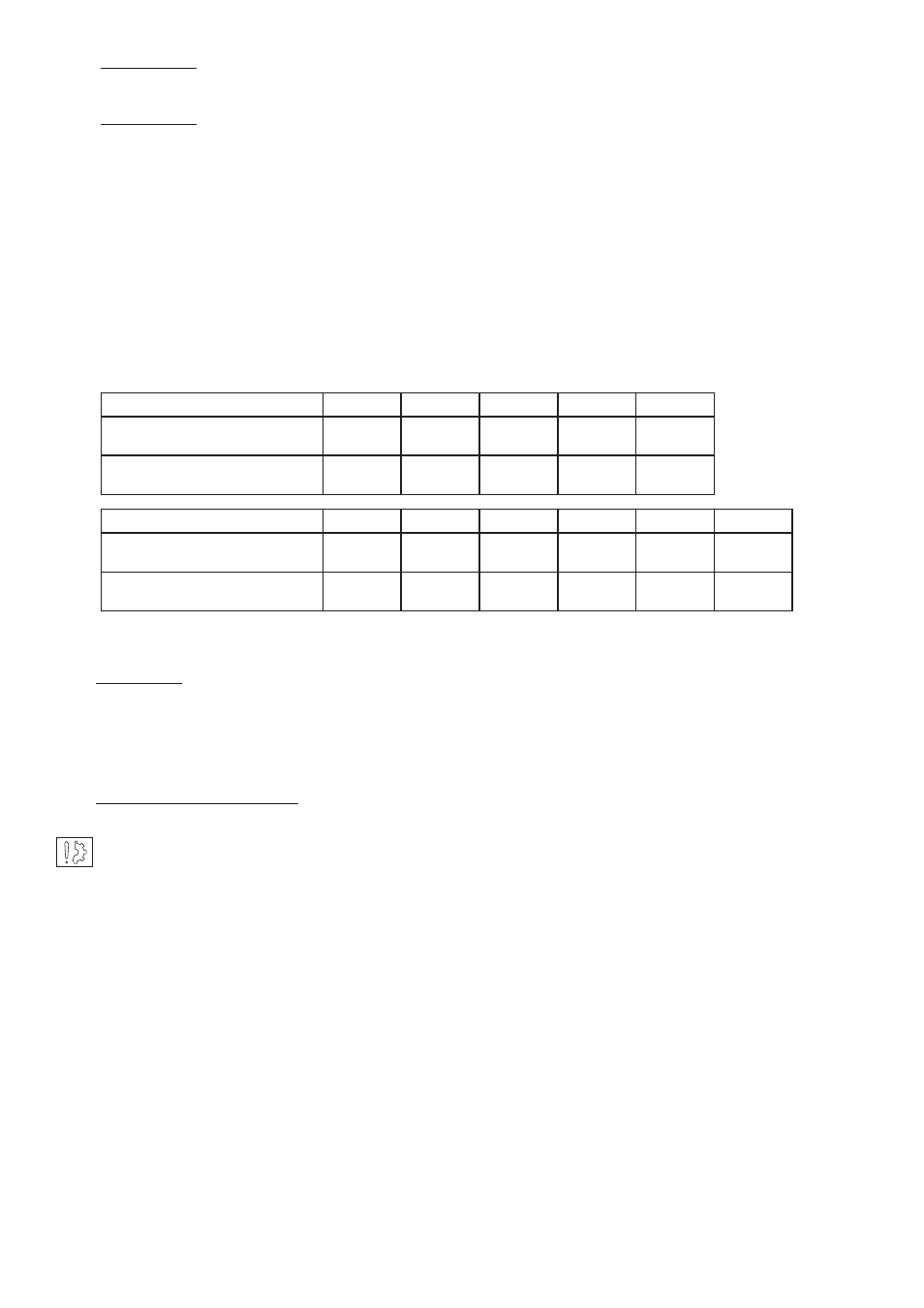

Check the wear on the disc set by measuring the travel of the piston (402), using table 2, below

4.2 Spare parts

All orders for spare parts must state the size of the unit with its code number, the reference number of the

part (see appendice), and the quantity of each component wanted.

4.3 Dismantling / reassembling

During

maintenance work, ensure that the mechanism to be driven by the clutch is at rest and that there is no

risk of it being started accidentally. Also ensure that the hydraulic supply is shut off.

Dismantling:

•

Remove the fixing screws from the cylinder (401) or closing flange (408)

•

Remove the cylinder (401) or closing flange (408)

•

Take out the piston (402)

•

Remove the worn disc set

•

Fit a new disc set

Size

100

200

400

800

1600

Initial travel

nominal (mm)

3

2,5

2,5

3

3

Travel, clutch

worn - max. (mm)

5,5

5

5

7

7,5

Size

3200

6400

12800

25600

51200

102400

Initial travel

nominal (mm)

5

5

5

5

6

6

Travel, clutch

worn - max. (mm)

10

11,5

12,5

14,5

17,5

17,5