Coil data, Burnishing and maintenance burnishing, Maintenance – Warner Electric Primary Brake Pin Drive Armature PB-825, PB-1000, PB-1225, PB-1525 Motor Brake and Spline Drive MB-825, MB-1000, MB-1225 Pin Drive User Manual

Page 10

10

Warner Electric • 800-825-9050

P-208 • 819-0367

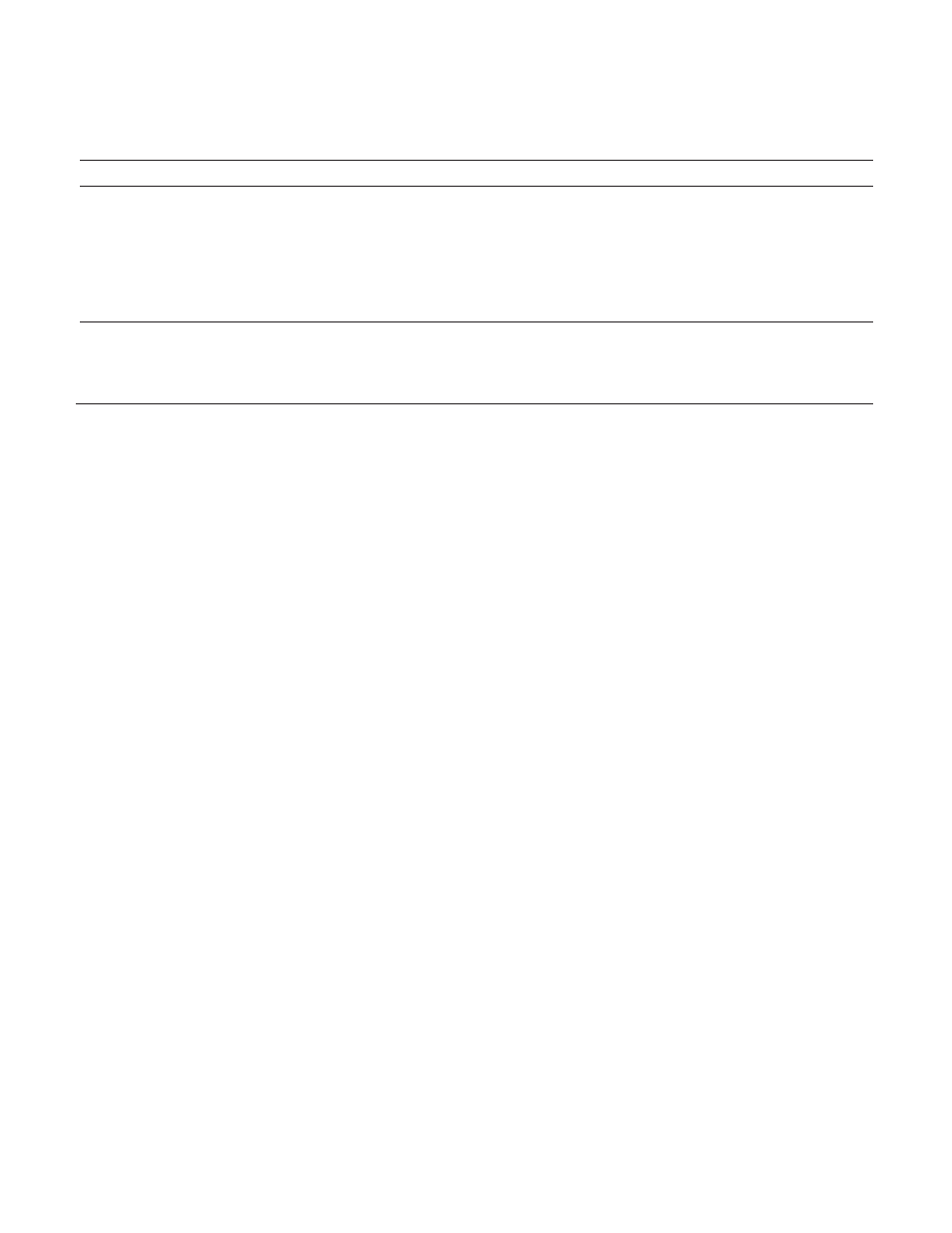

Coil Data

Unit Size

PB & MB-825

PB & MB-1000

PB & MB-1225

PB & MB-1525

Voltage — DC

6

24

90

6

24

90

6

24

90

6

24

90

Resistance @ 20°C — Ohms

1.27

20.4 223.3

1.23 19.7 248.7

1.33 22.3 261.7

1.45

19.8 258.4

Current — Amperes

4.74

1.18

.4

4.87 1.22

.36

4.5 1.08

.34

4.13

1.21

.35

Watts

28

28

36

29

29

33

27

26

31

25

29

31

Coil Build-up — Milliseconds

170

170

170

205

220

235

300

320

350

470

490

512

Coil Decay — Milliseconds

70

75

80

70

75

80

190

190

190

200

170

140

Notes: Build-up time equals current to approximately* 90% of steady state value and flux to 90%.

Decay time equals current to approximately* 10% of steady state value and flux to 10%.

*Approximately because current leads or lags flux by a small amount.

Burnishing and Maintenance

Burnishing

Intimate metal to metal contact is essential

between the armature and the metal rings (poles) of

the magnet or rotor. Warner Electric clutches and

brakes leave the factory with the friction material

slightly undercut to assure good initial contact.

Normally, the desired wearing-in process occurs

naturally as the surfaces slip upon engagement.

The time for wear-in, which is necessary to

obtain the ultimate torque of the unit, will vary

depending on speed, load, or cycle duty.

If maximum torque is required immediately after

installation, the unit should be burnished by slipping

the friction surfaces together at reduced voltage. It is

recommended that the burnishings be done right on

the application, if at all possible.

Burnishing at high speed will result in a smoother

wear-in pattern and reduce the time for burnishing.

The voltage should be set at approximately 30% or

50% of the rated value.

The unit should be cycled on and off to allow

sufficient time between slip cycles to prevent

overheating.

When a Warner Electric brake or clutch is

properly assembled and installed, no further

servicing, lubrication, or maintenance should be

required throughout the life of the unit.

Maintenance

Wear Pattern: Wear grooves appear on the

armature and magnet surfaces. This is a normal

wear condition, and does not impair functioning

of the unit. Normally, the magnet and armature,

as a mating pair, will wear at the same rate. It is

the usual recommendation that both

components be replaced at the same time.

Remachining the face of a worn armature is not

recommended. If a replacement armature is to

be used with a used magnet, it is necessary to

remachine the worn magnet face. In refacing a

magnet: (1) machine only enough material to

clean up the complete face of the magnet; (2)

hold the face within .005" of parallel with the

mounting plate; and (3) undercut the molded

facing material .001" - .003" below the metal

poles.

Heat: Excessive heat and high operating

temperatures are causes of rapid wear. Units,

therefore, should be ventilated as efficiently as

possible, especially if the application requires

fast, repetitive cycle operation.