2 main parts, Tank, Protection against corrosion – DE DIETRICH DIETRISOL TRIO DT 250 - TRIO DT 350 User Manual

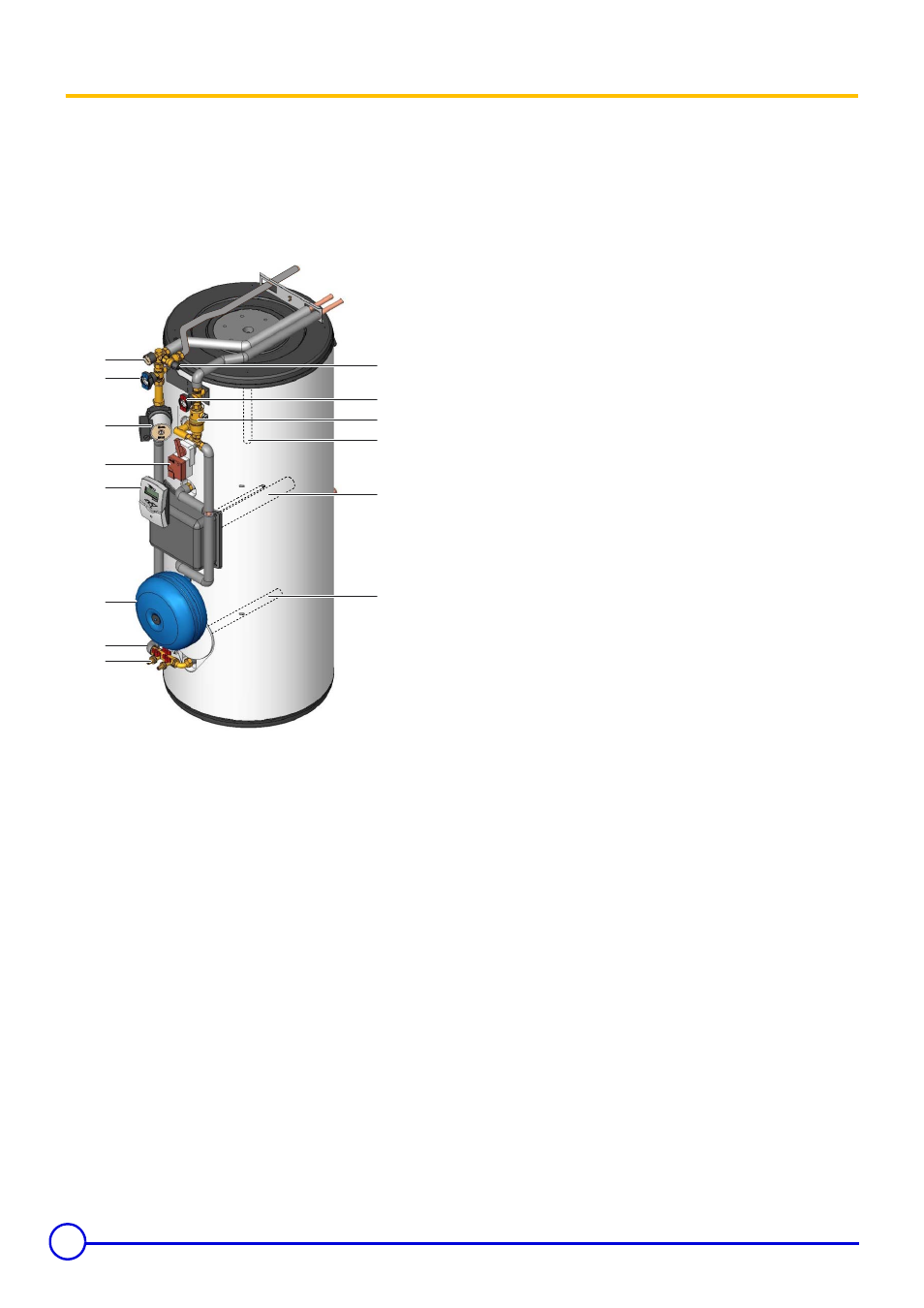

Page 8: Heat exchanger, Insulation, Casing, Solar station, Diemasol b regulator

8

TRIO DT 250 - TRIO DT 350

17/10/12 - 300028005-001-03

3.2 Main parts

Dietrisol TRIO DT ... is a high performance solar DHW tank/calorifier

designed to be connected to Dietrisol NEO or POWER solar

collectors and an De Dietrich central heating boiler.

It is designed in such a way as to be able to cope with a solar collector

surface area of up to 4.5 m

2

(DT 250) and 6.5 m

2

(DT 350) under the

conditions set out in the chapter "Hydraulic Connection Primary Solar

Circuit".

tank

The high quality steel tank is lined with food standard quality

vitrified enamel, which protects it from corrosion and preserves

all the qualities of the domestic water.

The Dietrisol TRIO DT ... tank is fitted with 2 heat exchangers

per zone for solar heating and one heat exchanger for

supplementary heating by means of a fuel oil or gas boiler.

Protection against corrosion

The tank is also protected from corrosion by two magnesium

anodes which must be inspected every 2 years and replaced if

necessary.

Heat exchanger

The thermal exchanger welded into the tank is made of smooth

piping, the inside of which, which is in contact with the domestic

water, is enamelled.

Insulation

The tank is strongly insulated with high strength rigid

polyurethane foam with no chlorofluorocarbons (CFC), 50 mm

thick to minimise heat loss.

Casing

The outside casing is made of painted steel sheeting.

The top and side covers are made of ABS.

Solar station

The solar heating pump unit comprises the solar circuit safety

unit, a pressure and temperature gauge and a flowmeter to

visualise circulation of the solar fluid between the panels and the

DHW tank. An expansion vessel is connected to the solar unit; it

is used to compensate for the expansion of the solar fluid in

which the temperature varies between 0 and 150°C.

Diemasol B regulator

The control system is the solar system's brain; it makes the solar

heating pump run at variable speeds according to the difference

in temperature between the bottom of the DHW tank and the

solar panels. The control system manages the set point

temperature (temperature to be attained in the DHW tank),

overheating and nighttime cooling. The control system also

displays the various operating modes, the temperatures in the

collectors and in the bottom of the DHW tank, as well as

signalling any malfunctions.

1

Pressure gauge - Primary solar circuit

2

Safety control unit for the solar circuit (6 bar)

3

Blue thermometer (tank solar heat exchangers outlet)

4

Red thermometer (tank solar heat exchangers inlet)

5

Primary solar circuit pump

6

Manual bleed degasser

7

2-position 3-way directional valve

8

Diemasol B regulator

9

8 l/6 bar expansion vessel, 2-bar pre-load

10

Automatic connection for expansion vessel

11

Primary solar circuit filling and draining device

12

Magnesium anode

13

Electric heating resistance

14

Magnesium anode

1

3

5

7

2

4

6

8

9

10

13

12

14

11

M001003