Caution, Installation guide, Operation – Veris Industries H971 Install User Manual

Page 2: Troubleshooting, Scaling, Span setting, Led indicator blink codes, Veris industries

VERIS INDUSTRIES

INSTALLATION GUIDE

H971/971SP

Z205412-0D

PAGE 2

©2009 Veris Industries USA 800.354.8556 or +1(0)503.598.4564 / [email protected]

09091

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

opEration

The H971 is a current-sensitive device that monitors DC current (amperage) in the

conductor passing through it. The unit uses Pulse Reset Technology™ with proven

transducer circuitry to produce a status output suitable for connection to building

controllers or other appropriate data acquisition equipment. The H971 requires 12-

24VDC to generate its output. The H971 has a user-adjustable span to allow flexibility.

The H971SP comes factory calibrated at a fixed span for maximum accuracy.

The H971 is ideal for DC current monitoring where accuracy must be maintained in

the presence of magnetic fields, current spikes, and high fault currents (e.g. solar

panels, electroplating equipment).

The H971 housing offers unprecedented mounting flexibility. The mounting bracket

can be attached in three different places. Additionally, the bracket is compatible with

the Veris AH01 DIN Rail clip, allowing DIN mounting.

troublEshooting

Problem

Solution

The LED is off and no signal is

produced

Verify that at least 12V supply voltage is applied to PWR

(+) and GND (-) terminals.

The LED is on solid and the

output is at maximum

Verify that the unit is not attempting to monitor more

than ±200A.

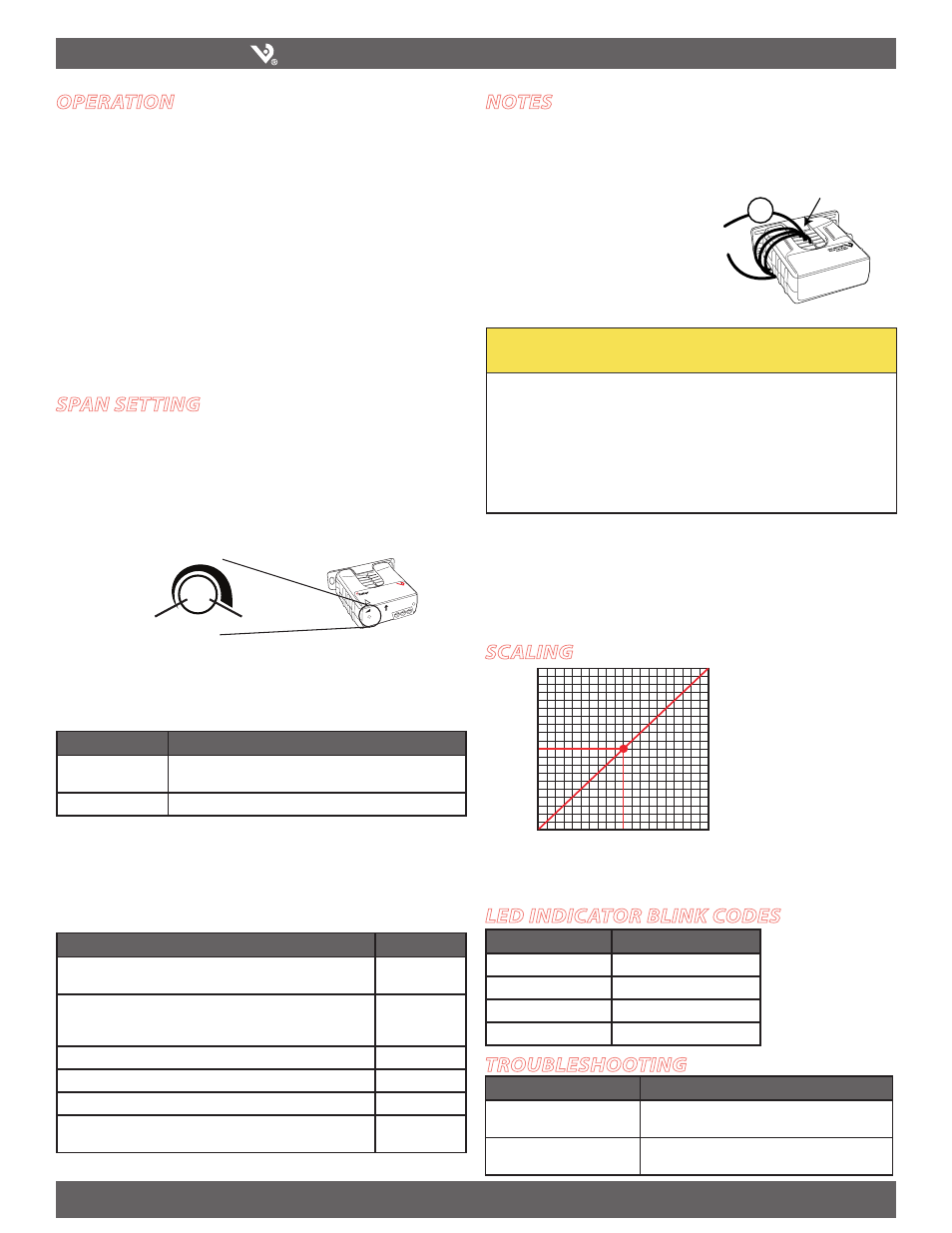

scaling

SENSED AMPS

4mA

12mA

-200A*

+200A*

0A

20mA

SENSOR OUTPUT

*Field Adjustable from ±20A to ±200A

(not applicable to customer-specified factory scaled models)

span sEtting

(not applicable to the H971SP models)

The H971 comes preset at the maximum (0-200A) span. To adjust the H971 to a

different span, locate the potentiometer on the top of the device. This potentiometer

is a multi-turn device, taking about 23 turns to adjust the span from ±20A to ±200A.

Use the potentiometer to adjust the maximum amperage range used by the sensor.

The smallest amperage range (0 to ±20 A) is set by turning the potentiometer fully

counterclockwise; the greatest amperage range (0 to ±200 A) is set by turning the

potentiometer fully clockwise.

S

E

I

R

T

S

U

D

N

I

S

I

R

E

V

3

2

2

7

9

n

o

g

e

r

O

,

d

n

a

lt

r

o

P

6

5

5

8

-

4

5

3

-

0

0

8

-

1

1

7

9

!

Span

Current

Flow

4-20

mA

12-24

VDC

Gnd P

ower

200A DC Current Sensor

Fully CCW:

smallest range

(0 to 20A)

Fully CW:

greatest range

(0 to 200A)

To determine the best amperage range for an application, first set the load to

the maximum amperage that will be used. Use the LED as a guide to adjust the

potentiometer to its optimum setting. Verify the measured output current matches

the load current using a current clamp meter.

LED Activity

Potentiometer Adjustment

Steady green blink

Turn CCW until LED blinks rapidly, then slowly turn CW just until

blink returns to steady rate.

Rapid green blink

Turn CW until LED blinks at a steady rate.

An alternate adjustment method that does not require a current clamp meter can

also be used, provided the amperage flowing in the conductor is steady for the

duration of the adjustment. In this example, it is assumed that the H971 is initially

set to the maximum 0-200A span, but the installer has decided to reduce the span to

0-120A. Sample numbers are provided to illustrate the calculations.

Action

Example

Determine the device output using a portable multimeter or the

automation controller.

15

The H971 is bi-directional, so a 12mA output corresponds to a 0A

load in the conductor. Determine the output above the 0 level by

subtracting 12mA.

15 - 12 = 3

Multiply by the initial maximum span setting before adjustment.

3 x 200 = 600

Divide by the desired maximum span.

600 / 120 = 5

Add 12 to this value to get the new output value.

5 + 12 = 17

Turn the potentiometer counterclockwise until the output reads 17mA.

This is the output for the amperage load at a span of 0-120A.

17

notEs

For load currents less than 2A:

Wrap the monitored conductor through the center hole and around the sensor body

to produce multiple turns through the "window." This increases the current measured

by the transducer.

Controller must be programmed to account for

the extra turns. e.g., if four turns pass through

the sensor (as shown) the normal controller

reading must be divided by 4.

Accuracy may be reduced if wraps are used.

4x

1A

CAUTION

RISK OF EQUIPMENT DAMAGE

• Derate the product’s maximum current for the number of turns

through the sensing window using the following formula.

Rated Max. Amps ÷ Number of Turns = Max. monitored Amps

e.g. : 100A ÷ 4 Turns = 25 Amps max. in monitored conductor

• Failure to follow these instructions can result in overheating

and permanent equipment damage.

Failure to observe the following can result in incorrect output readings:

Observe the arrow on the H971 showing positive current direction so that the

1.

output will have proper polarity for the application.

Do not expose the H971 to continuous current levels greater than 200A RMS (brief

2.

current surges and fault currents should not adversely affect the H971).

lED inDicator blink coDEs

LED Activity

Status Description

Single green

Normal operation

Double green

Over span

Red/green

Over limit

Solid red

Overload