24 dealer service, Dealer service – Woods Equipment 7000 User Manual

Page 26

24 Dealer Service

MAN0137 (9/14/01)

DEALER SERVICE

Cont’d

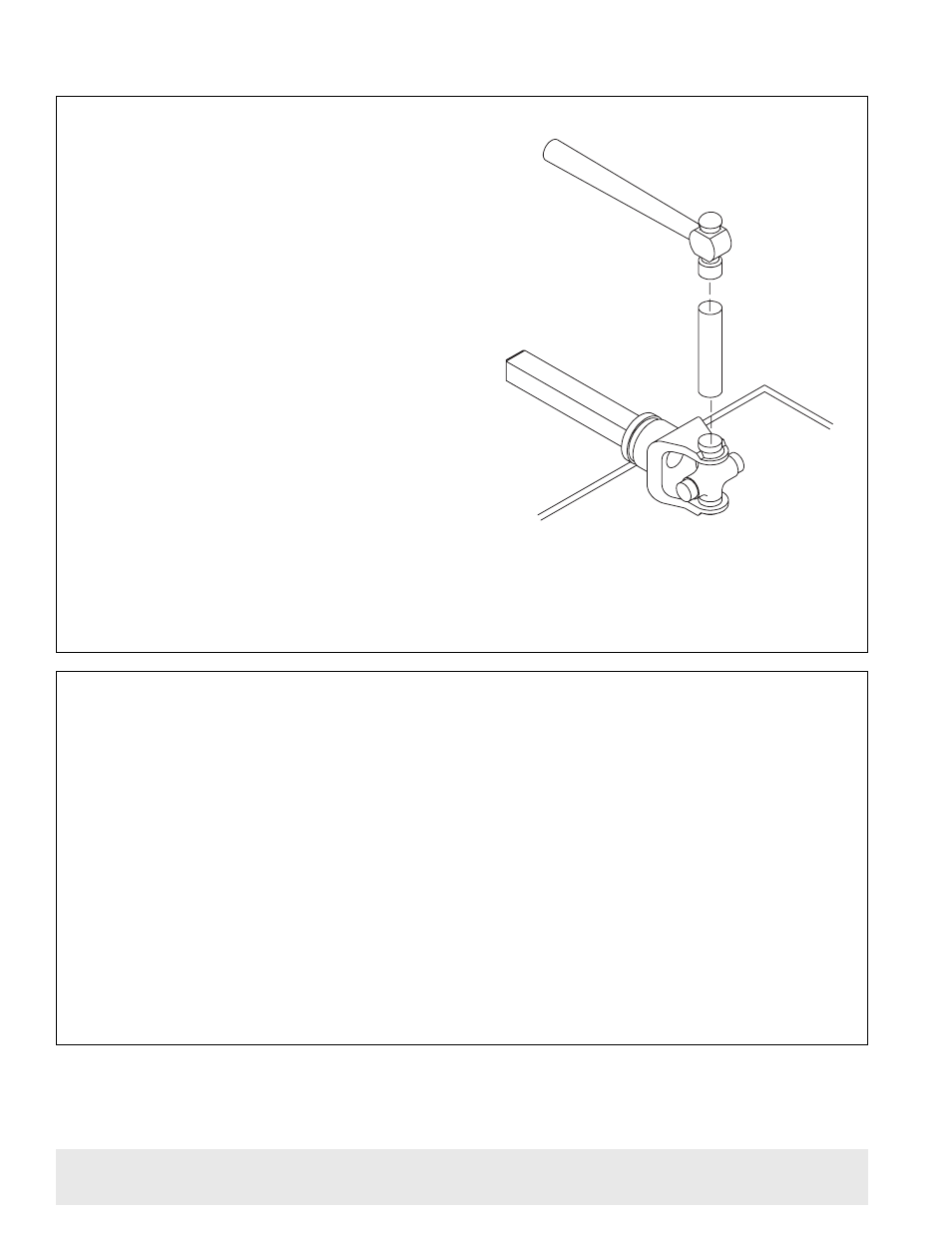

Assemble U-Joint

1. Place seals securely on bearing cups. Insert cup

into yoke from outside and press in with hand pres-

sure as far as possible.

2. Insert journal cross into bearing cup with grease

fitting away from the shaft. Be careful not to disturb

needle bearings.

3. Insert another bearing cup directly across from

first cup and press in as far as possible with hand

pressure.

4. Trap cups in vise and apply pressure. Be sure

journal cross is started into bearings and continue

pressure with vise, squeezing in as far as possible.

Tap yoke to aid in process.

5. Seat cups by placing a drift or socket (slightly

smaller than the cup) on cup and rapping with a ham-

mer. See Figure 18.

6. Install snap ring and repeat on opposite cup.

7. Repeat steps 1 and 2 to install remaining cups in

remaining yoke.

8. Move both yokes in all directions to check for free

movement. Should movement be restricted, rap on

yokes sharply with a hammer to relieve any tension.

Repeat until both yokes move in all directions without

restriction.

Figure 18

GEARBOX MAINTENANCE

Read this complete section before starting any repair.

Many steps are dependent on each other.

Gearbox bearings, gears, and shafts have an interfer-

ence press fit. Gearbox repair is limited to seal, gas-

ket, and vent plug replacement.

Always maintain correct gear lube level in gearbox.

Be sure proper vent plug is installed.

Troubleshooting is an important part of gearbox main-

tenance. Check for leakage and bad bearings.

Leakage is a very serious problem and must be cor-

rected immediately or damage to gearbox and belt

will result. Remove gearbox from mower to repair

leakage problems.

Leakage may be caused by a vent plug not venting.

To check vent plug operation, remove plug and apply

low air pressure to opening in side of plug. Check to

make sure it is venting out of the top.

Operating gearbox with improper lube level may also

cause seals to leak. Also check for housing cracks. If

any of these conditions exist, correct them, clean area

where leakage was evident, return mower to service,

and check to make sure leakage has been stopped.

Bearing maladjustment or failure is indicated by noise

and excessive side and end play in gear shafts. If this

is indicated, replace the gearbox.

CD1389