Two springs (6) split solid shaft, Four springs (6) split solid shaft – Wayne-Dalton THERMOMARK 5150 User Manual

Page 7

5/16 X 1 Self drilling & tapping screw

for use on steel jambs.

3/8 X 3 Sleeve anchor for use on

pre-cast concrete.

( Drill a 3/8 x 3-1/2 deep hole)

5/16 X 1 5/8 Lag

screw for use on

wood jambs.

Angle out (wood

jambs)

Reverse angle

(steel or precast/block)

13

30or

18

24

24

24

10

NOTE: Typical

fastener spacing.

Install hardware onto left side of

section, install roller into vertical

track, rotate the section into

position and stack, align sections

and secure right hand hardware.

Fig. L

PG. 7

Wind springs toward ceiling.

(Standard lift applications)

PG. 10

Fig. M

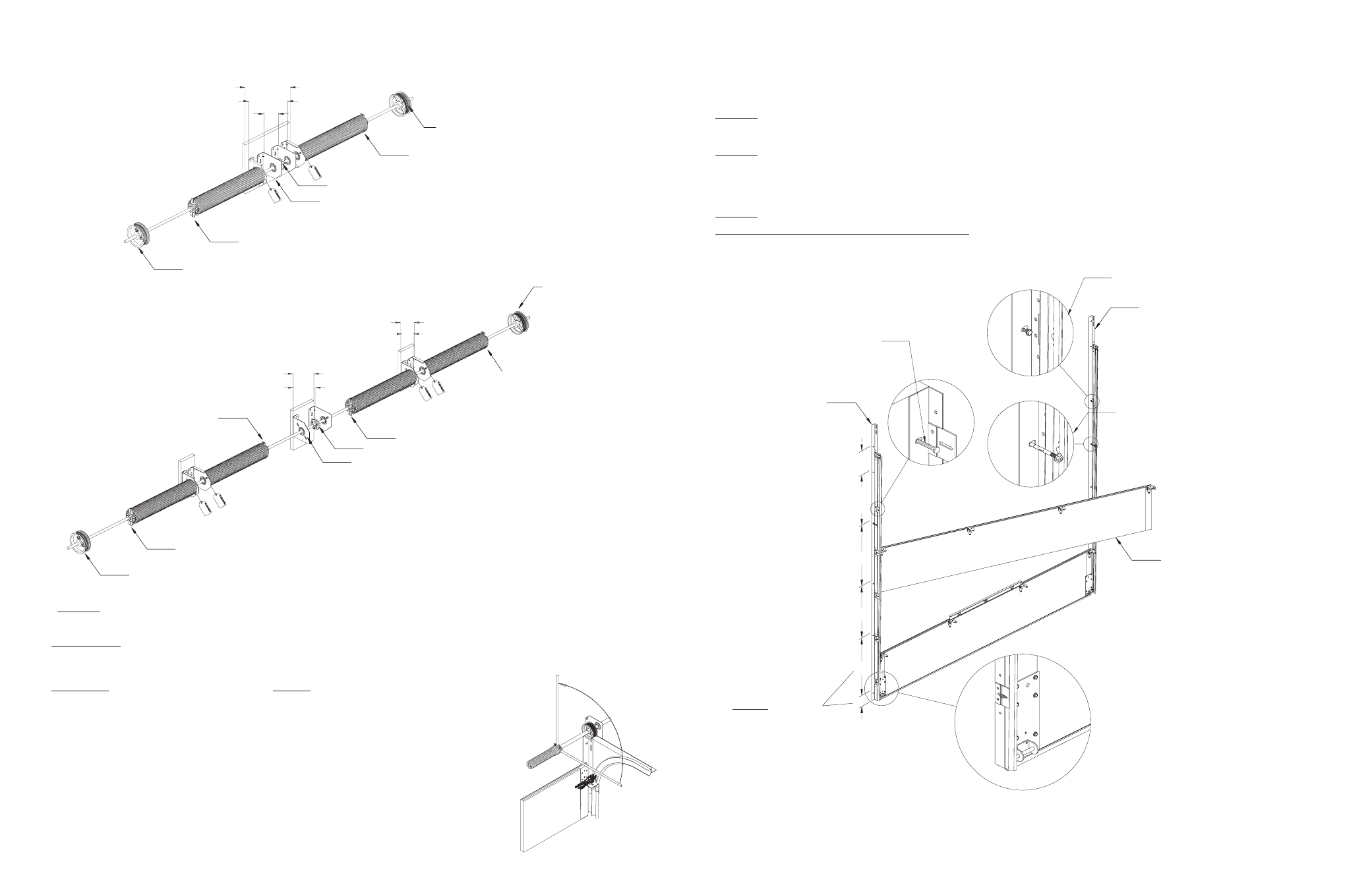

RIGHT HAND DRUM

BLACK

EXTRA SUPPORT BRACKET USED WITH SPLIT SHAFT

COUPLING (SEE NOTE * )

LEFT HAND DRUM

RED

WINDING CONE

RED

WINDING CONE

BLACK

TWO SPRINGS

(6)

SPLIT SOLID

SHAFT

13

20

24 MINIMUM SPRING PAD

WIDTH

FOUR SPRINGS

(6)

SPLIT SOLID

SHAFT

EXTRA SUPPORT BRACKET USED

WITH SPLIT SHAFT

COUPLING (SEE NOTE * )

8 MIN.

SPRING

PAD

7

12 MIN.

PAD

WIDTH

13

WINDING CONE RED

WINDING CONE BLACK

RIGHT HAND DRUM

BLACK

WINDING CONE BLACK

WINDING CONE RED

LEFT HAND DRUM

RED

spacing is achieved.

Doors over 11 ft. high and over 14ft. wide must have (1) intermediate drop hanger as shown in Fig. S on Page 13.

Doors between 16 and 18 high must have (2) intermediate drop hangers as shown in Fig. S on Page 13.

Doors over 18 high must have intermediate drop hangers placed on 6 centers.

STEP 13: Release the locking pliers from vertical track and check the doors counterbalance.

Adjust springs if necessary.

STPE 14: Vertical tracks can now receive final adjustments. Open and close the door a few times, checking and adjusting side

clearance (if necessary). Tighten jamb fasteners (lags, teks, or anchors) to permanently secure verticals. Adjust door in or out

from jamb by loosening the track to obtain proper seal. Permanently tighten all track bolts. Adjust top bracket roller carrier so

that the top section is sealed against header.

STEP 15: Lubricate springs, rollers, and bearing with oil.

DO NOT GREASE THE INSIDE OF THE TRACKS.

WARNING: Apply locking pliers to the tracks ABOVE the third

roller, or lock door if applicable, before winding the spring(s) to

prevent door from rising unexpectedly, possibly resulting in severe

injury or death.

Wind spring 1/4 turn at a time to the number of complete revolutions

recommended on the spring tag. Wind up as shown Fig. M. When the

proper number of turns is reached, tighten the set screws on the

winding cone. Release the vice grips from the spring shaft(s). Adjust

the coupler on split solid shafts until drums are in time (check door

level) and tighten coupler.

WARNING: Winding bars must fit snuggly into holes in spring winding cones. Attempting to wind

springs with loosely fitting rods, screwdrivers or other improper tools can result in sever injury or death.

*NOTE: COUPLING USED ON SOLID SHAFT ONLY. TIGHTEN CONNECTING BOLTS AFTER

WINDING SPRING.

RED WINDING CONES ALWAYS POINT TO THE LEFT

SIDE

BLACK (OR PLAIN) WINDING CONES ALWAYS POINT THE

RIGHT SIDE,

STANDING INSIDE OF THE BUILDING, LOOKING OUT.

RED DRUMS GO ON THE LEFT SIDE

BLACK DRUMS GO ON THE RIGHT SIDE