Spring turn chart, Broken cable safety device installation, Fig. r – Wayne-Dalton THERMOMARK 5150 User Manual

Page 5: Fig. x

PG. 5

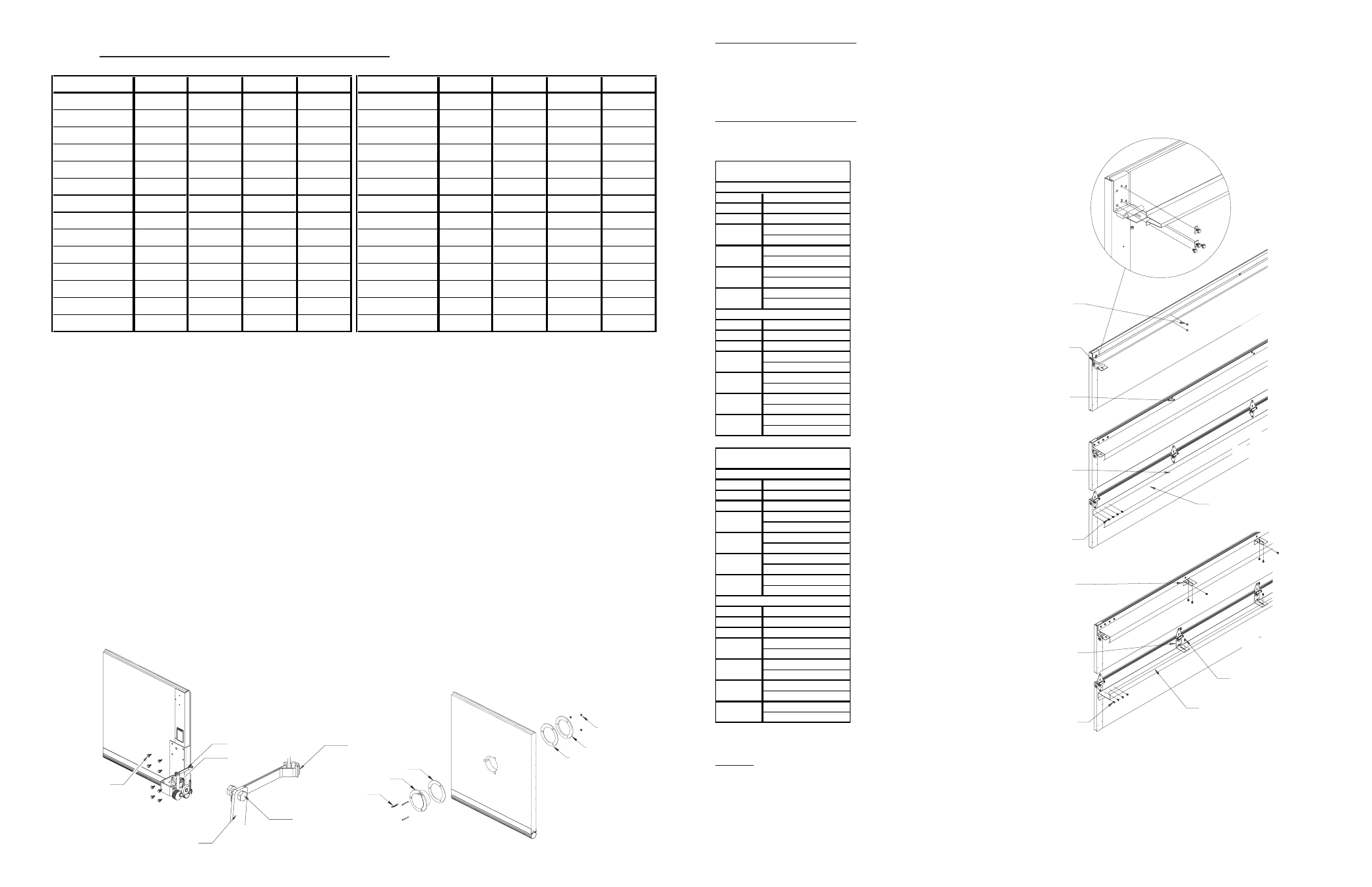

STEP 4. MODEL 5150 & 5200 U-bars & struts to be secured to the section using (2) 1/4 - 20 x 7/8 TEK screws at each end.

Additional 1/4 - 20 x 7/8 TEK screws will need to be used at each hinge location.

U-bars and struts are to be mounted at the top of section under hinges and across top brackets, as seen in Fig. K. Refer to

STRUTTING SCHEDULE for strut placement.

NOTE: Strut clips used at top bracket. If strutting is required for a raised panel, glazed section, place

U-bar over hinge leaf and attach with 1/4 self-drilling/tapping screws and strut clips.

STEP 4. MODEL 5155 & 5255 U-bars are to be secured to the sections using 1/4 - 20 x 7/8 TEK screws and strut clips. Mount

U-bars at top of section, across hinge leafs and top brackets.

Fig. K

(Top (2) Section Shown)

Top bracket installation illustration.

Secure each bracket using (4) 1/4

- 20 x 7/8

self-drilling/tapping screws and (2)strut clips.

Doors over 142 wide require double top

brackets.

Place (2) 1/4 - 20 x 7/8

self-drilling/tapping screws

at each hinge location.

3 U-Bar

Fasten using (2) 1/4 - 20 x 7/8

self-drilling/tapping screws

at each

hinge location.

Fasten using (4) 1/4-20 x 7/8

self-drilling/tapping screws

.

Attach Girt at end of section

using (4) 1/4-20 x 7/8

self-drilling/tapping screws

.

6 Girt

Door Widths

Strutting

8’ 0" - 10’ 2" None

10’ 3" - 14’ 2" (1) 2" U-Bar

(1) 3" U-Bar

Every Other Section

(1) 3" U-Bar (20 Ga.)

Every Section

(1) 3" U-Bar (16 Ga.)

Every Section Plus 1

(1) 6" Girt

Every Other Section

Door Widths

Strutting

8’ 0" - 10’ 2" None

10’ 3" - 12’ 2" (1) 2" U-Bar

(1) 3" U-Bar

Every Section Plus 1

(1) 3" U-Bar (20 Ga.)

Every Section

(1) 3" U-Bar (16 Ga.)

Every Section Plus 1

(1) 6" Girt

Every Other Section

5150 & 5155 Strutting Schedule

Standard Section Reinforcement

Non-Brown Doors

20’ 3" - 26’ 2"

18’ 3" - 20’ 2"

16’ 3" - 18’ 2"

14’ 3" - 16’ 2"

20’ 3" - 26’ 2"

Brown Doors

12’ 3" - 16’ 2"

16’ 3" - 18’ 2"

18’ 3" - 20’ 2"

Door Widths

Strutting

8’ 0" - 12’ 2" None

12’ 3" - 14’ 2" (1) 2" U-Bar

(1) 2" U-Bar

Every Other Section

(1) 3" U-Bar

Every Section Plus 1

(1) 3" U-Bar (20 Ga.)

Every Section Plus 1

(1) 6" Girt

Every Other Section

Door Widths

Strutting

8’ 0" - 10’ 2" None

10’ 3" - 12’ 2" (1) 2" U-Bar

(1) 2" U-Bar

Every Other Section Plus 1

(1) 3" U-Bar

Every Other Section Plus 1

(1) 3" U-Bar (20 Ga.)

Every Section Plus 1

(1) 6" Girt

Every Other Section

5200 & 5255 Strutting Schedule

Standard Section Reinforcement

Non-Brown Doors

14’ 3" - 16’ 2"

16’ 3" - 18’ 2"

18’ 3" - 20’ 2"

20’ 3" - 26’ 2"

16’ 3" - 18’ 2"

18’ 3" - 20’ 2"

20’ 3" - 26’ 2"

Brown Doors

12’ 3" - 16’ 2"

STEP 5. Center and level (or support to a known grade level) the bottom section in the opening, as seen in Fig. K. Temporarily

attach the vertical tracks to the jambs. Allow 1/2 clearance between the section and the track as illustrated in the sideroom

illustrations (page 3).

It is important that the top of each track is at the same level. (shim if necessary)

Products being installed to precast or block must use a 3/8 x 3 long sleeve anchor to attach the verticals to the building. Use the

slots in the wall angle as a drill template, drill a 3/8 hole (3-1/2 deep) and secure to anchor.

SPRING TURN CHART

DOOR HEIGHT

400-8

400-12

5250-18

800-32

6’6"

7 1/2

7 1/2

7’0"

7 7/8

7 7/8

7’6"

8 1/2

8 1/2

8’0"

8 7/8

8 7/8

6 3/4

8’6"

9 1/4

7 1/8

9’0"

9 1/2

7 3/8

9’6"

10 1/8

7 3/4

10’0"

10 1/2

8 1/8

5 3/8

10’6"

11

8 3/8

5 5/8

11’0"

11 1/2

8 7/8

5 7/8

11’6"

12

9 1/8

6

12’0"

12 1/2

9 1/2

6 1/4

12’6"

9 7/8

6 1/2

13’0"

10 1/4

6 3/4

DOOR HEIGHT

400-8

400-12

5250-18

800-32

13’6"

10 1/2

7

14’0"

10 7/8

7 3/8

14’6"

11 1/4

7 1/2

15’0"

11 1/2

7 5/8

15’6"

11 7/8

8

16’0"

12 1/4

8 1/8

16’6"

12 1/2

8 1/4

17’0"

12 7/8

8 5/8

17’6"

13 1/4

8 7/8

18’0"

13 1/2

9

18’6"

9 1/4

19’0"

9 1/2

19’6"

9 3/4

20’0"

9 7/8

Broken Cable Safety

Device (SES)

Broken Cable Safety Device Installation

5/8 X 20 self-drilling

TEK screw (8)

Cable Arm

Cable Arm

PG. 12

Fig. R

1-1/2 X #10 Counter

Sunk Bolt (3)

Exhaust Port

Gasket

Fig. X

Gasket

#10 Hex Nuts (3)

(1) Attach the broken cable safety device, with cable attached, to the section

using (8) 1/4-20 X 5/8 self-drilling TEK screws (as seen in Fig. R.).

(2) Place the bottom section in the opening.

(3) Install the verticals over the rollers.

(4) Follow the rest of the door installation per the instruction manual.

(5) After the door installation is complete, rotate the cam arm up, and connect the

cable arm to the cam arm with the clevis and cotter pins.

(6) Operate the door to verify that there is clearance between the track and section

for the cable arm.

(7) Adjust the track as needed.

6 Girt

Fasten using (2) 1/4-20 x 7/8

self-drilling/tapping screws

and

(1) L Bracket at each hinge location.

Install L Bracket over lower hinge leaf.

(1) 1/4-20 x 7/8

self-drilling/

tapping screws

.

Strut clips are

required, on

raised panel,

glazed sections

(Top Section Shown)

Fasten using (2) 1/4 - 20 x 7/8

self-drilling/tapping screws

at each

hinge location.

Fasten using (5) 1/4 - 20 x 7/8

self-drilling/tapping screws

and

(1) L Bracket at each hinge location.

5150/5200

Girt Attachment

5155/5255

Girt Attachment

Outside Trim Ring

#10 X 1-1/2 BOLT

W/LOCK NUT

Cam Arm

Cam Arm