Important, Lubrication, Vacuum motor maintenance – Nilfisk-Advance America 56262214 User Manual

Page 13: Vacuum motor airways

FORM NO. 56041590 / AX 300 / AX 400 - 13

LUBRICATION

Once a month, wipe the solution valve with a clean cloth. Then use a spray silicone lubricant on all pivot points associated with the valve

assembly, especially the valve plunger.

Once a month, lubricate the pivot points of the handle and the wheel axles. Wipe off any excess to avoid staining floor surfaces.

The Solution Valve Assembly is located on the bottom of the machine.

Valve Plunger

VACUUM MOTOR MAINTENANCE

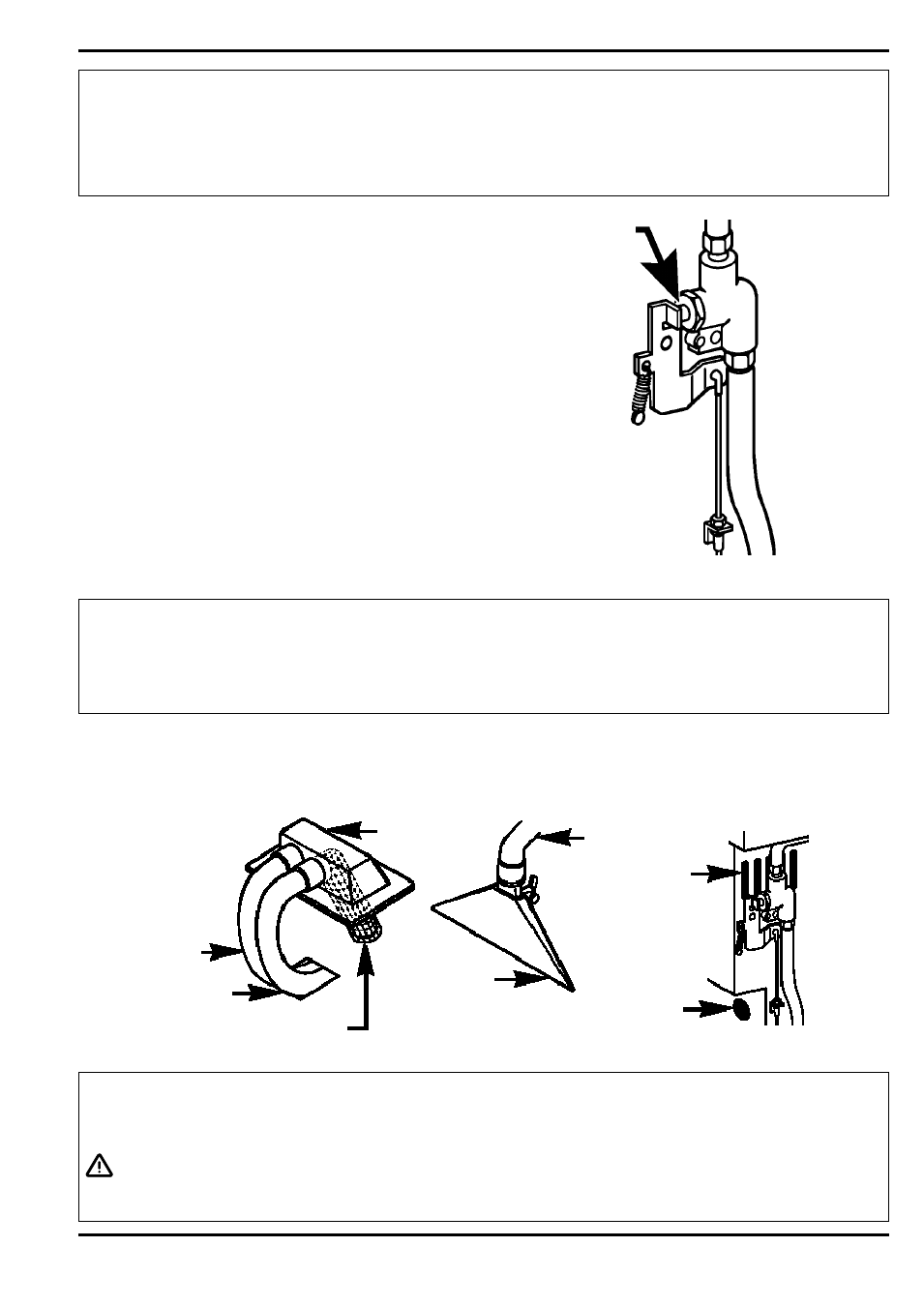

Once a month, check the vacuum motor to make sure the airways are not blocked. Clean the dome lid on the recovery tank thoroughly.

Clear hoses of debris and keep the vacuum motor exhaust area clean.

Vacuum Exhaust

Float Ball and Cage

Vacuum Hose

VACUUM MOTOR AIRWAYS

Dome Lid

Recovery Hose

Recovery Hose

Vacuum Exhaust

Pick Up Tool

Have Nilfisk check the carbon motor brushes once a year or after 500 operating hours. Replace the carbon brushes if they are worn to 9.5

mm or less.

IMPORTANT!

Motor damage from failure to service the carbon brushes is not covered under warranty.