Maintenace schedule, Medical package system – Powerex Medical Packing System MPQ User Manual

Page 5

Tank

Drain moisture

Daily

2500

Inlet air filter

Replace

●

▲

(Every 2,500 hrs or less)

Blower fan

Clean

●

●

●

●

Fan Duct

Clean

●

●

●

●

Compressor Fins

Clean

●

(Every 2,500 hrs or less)

Bearings

Replace

●

●

▲

Compression rings Replace

▲

▲

Wrist pin bearing

Regrease

▲

▲

Piston set

Replace

▲

V-belt

Inspect, replace

*Note 3

●

▲

▲

▲

▲

Safety valve

Confirm operation

●

(Every 2,500 hrs or less)

Pressure gauge

Inspect

●

(Every 2,500 hrs or less)

Air leaks

Inspect

●

●

●

Filters

Replace

▲

▲

▲

▲

▲ (View delta pressure

indication)

Moisture drains

Inspect

●

●

●

traps

Suction pressure

●

●

●

●

●

(refrigerated)

Heat exchanger

●

●

●

●

●

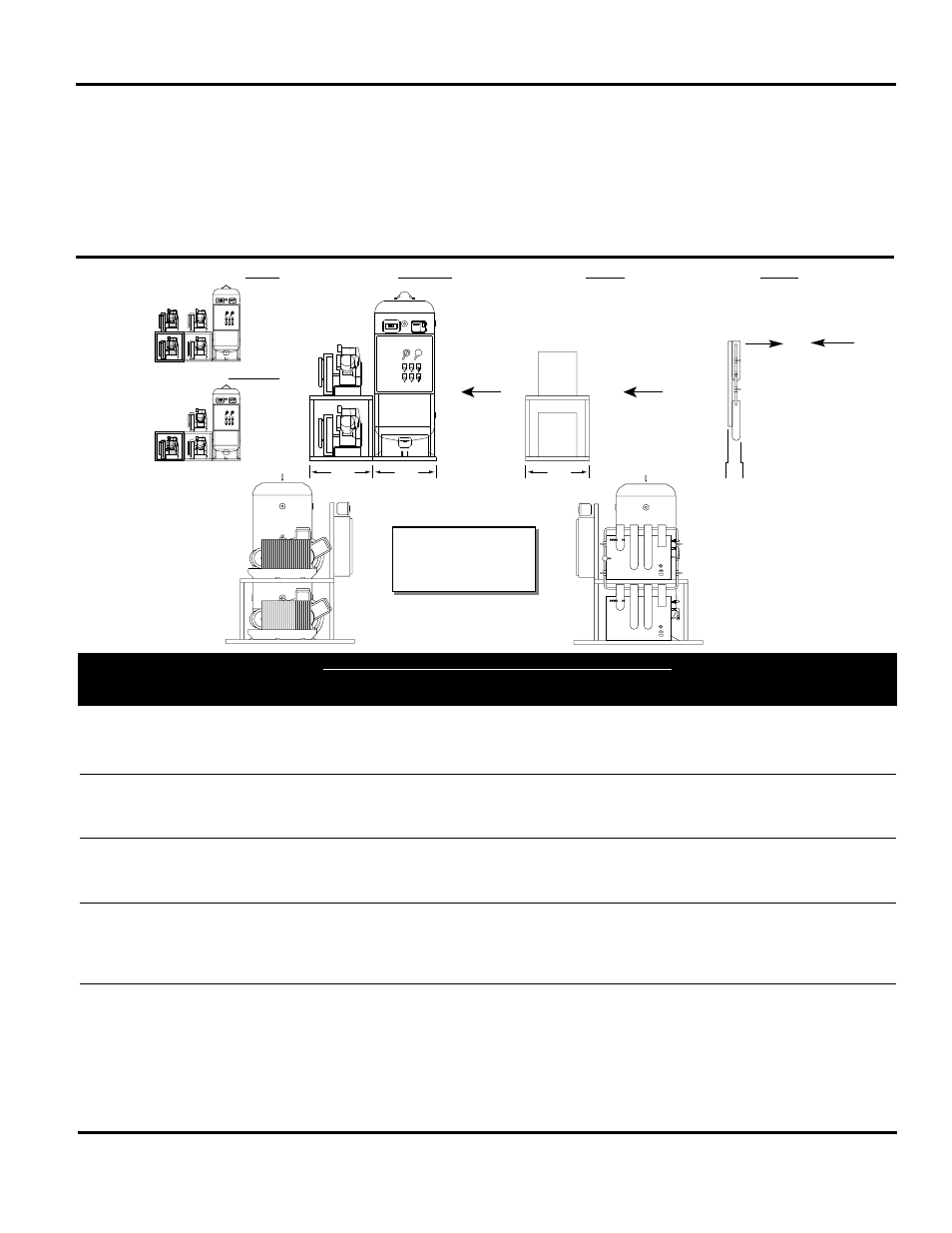

Medical Package System

COMPRESSOR MAINTENANCE SCHEDULE

Operating Hours

Item

Action needed

500

2500

5000

10,000

15,000

20,000

Remarks

QUADPLEX MPQ

TRIPLEX MPT

DUPLEX MPD

DRYER SYSTEM

MDR OR MDD

FILTER SYSTEM

MFP

LEFT

END

VIEW

RIGHT

END

VIEW

Consult factory

for special voltages

or arrangements.

32"

32"

8"

32"

5

1. Inspect and perform maintenance periodically according to maintenance schedule.

2. The maintenance schedule relates to the normal operating conditions. If the circumstances and load condition are adverse, shorten the cycle time and do

maintenance accordingly.

3. * The tension of the V-belt should be adjusted during the initial stage and inspected every 1,500 hours afterwards. Proper belt tension for 3/4 to 3 HP units is

12 lbs./.5” deflection; for 5 to 20 HP units, 16 lbs./1.5” deflection

● Inspect ▲ Replace

+

+

facing the black fan shroud and

counterclockwise if facing the

compressor flywheel.)

c. Set both selector switches to the

auto position. Compressors will

both run until the lead pressure

switch closes.

d. Open valve at the air receiver

leading to Medical Air System.

e. Check for air leaks at the

connections.

9. Check that the compressor operates

without excessive vibration, unusual

noises or leaks.

10. Check the discharge pressure. Also

make sure the air pressure rises to the

designated pressure setting by

checking the discharge pressure

gauge.

11. Check the operation of the pressure

switch or the pilot valve for

continuous run units by opening

the stop valve and confirming the

compressor starts or reloads as

pressure drops.