Êten s io n settin gs, Ëbelt tension measurements – Milnor K36 0005R User Manual

Page 4

MS

SM0

2

0

4

AE

/8

33

2BV

(1

of

1)

È

V-BELT TENSION ADJUSTMENTS FOR

30" AND

36" B-TYPE

M

ACHINES AND

42" Q-

TYPE MACHINES

This

ins

truct

ion i

s t

o

be us

ed for

adjus

ti

ng t

h

e bel

t

tens

ion

on t

h

e fol

lowi

n

g

m

achine m

odes:

30016B

WE

42026QHE

36021B

WE

42026QTG

360326QWE

42026QTH

42026QWE

A belt

tens

ion t

est

ing devi

ce (Mi

lnor

®

part

num

ber 30T001)

and

a

st

raight

edge are required when us

ing t

h

ese i

n

st

ructi

ons.

Ê

Ten

s

io

n Settin

gs

Set

the o-ri

ngs on t

h

e tens

ion t

est

ing devi

ce (see F

IGURE 1) as

foll

ows:

1.

M

ove the upper o-ri

ng to t

h

e topm

ost

posi

ti

on, rest

ing agai

nst

the bot

tom

edge of the cap.

2.

F

ind t

h

e proper belt

deflect

ion s

ett

ing (by m

achine m

odel and bel

t funct

ion) i

n

the appropri

ate t

able bel

o

w.

3.

M

ove the l

o

wer o-ring on t

h

e tens

ion t

est

er to t

h

is

deflect

ion s

ett

ing on t

h

e inches

scal

e.

NOT

E

1:

The t

ensi

on tes

ti

ng device i

s m

arked on the one s

ide i

n

inches

and pounds and on t

h

e other s

ide i

n

cen-

ti

met

ers and ki

logram

s. Al

l val

u

es i

n

the t

ables

are marked.

NOT

E

2:

The i

n

st

ructi

on sheet

provided wi

th t

h

e tens

ion t

est

ing devi

ce shoul

d not be us

ed. Use onl

y the i

n

st

ruc-

ti

ons provi

ded herein.

NOT

E

3:

The reference (ref.) codes

shown i

n

the t

ables

are for factory us

e

only.

Ë

Belt Tension Measurements

1.

Place a s

trai

ght edge al

ong the t

op edge of the bel

t t

o

be tes

ted s

o

that

it

spans bot

h pull

eys. P

lace t

h

e tension t

est

er in t

h

e center of t

h

e belt

and press

and down on the cap unt

il

the l

o

wer o-ring i

s i

n

li

ne wit

h

the s

trai

ght edge, as

shown.

2.

R

ead the s

ett

ing of t

h

e upper o-ring on t

h

e LBS

scal

e of the t

ensi

o

n

te

st

er

.

3.

Com

p

are thi

s val

u

e wit

h

the accept

able range i

n

the appropri

ate t

able.

If the bel

t i

s brand new (has

never been run), use t

h

e range in t

h

e In-

it

ia

l Tension col

u

mn. If t

h

e belt

is not brand new, l

o

cate t

h

e accept

-

able range i

n

the F

inal

Tensi

on colum

n

.

4.

If t

h

e reading on t

h

e tens

ion t

est

er is

les

s t

h

an the range s

hown in t

h

e tabl

e, the bel

t i

s t

oo loos

e and mus

t be

ti

ghtened. If t

h

e reading i

s great

er than t

h

e range shown i

n

the t

able, t

h

e belt

is

too t

ight

and mus

t be l

oos-

ened. Adj

u

st

the bel

t unt

il

the readi

ng fall

s wi

thi

n

the accept

able range i

n

the t

able.

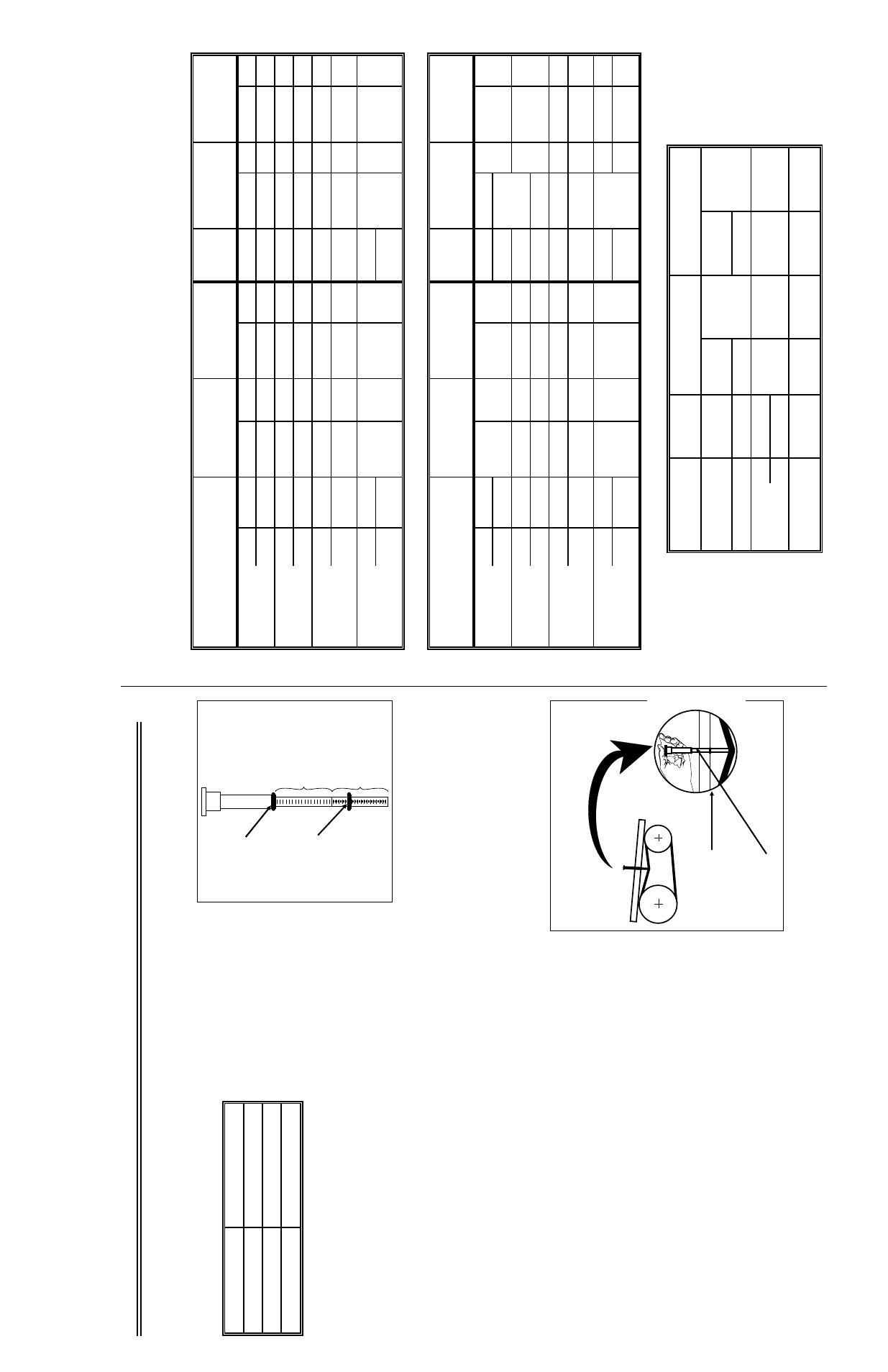

Ï

30016BWE 36021BWE

Be

lt

Def

lect.

(i

nches)

Init

ia

l

Tensio

n

(l

bs

.)

(ref

.)

Init

ia

l

Tensio

n

(l

bs

.)

(ref

.)

Be

lt

Deflect

(I

N)

Init

ia

l

Te

n

si

o

n

(lbs

.)

(ref

.)

Init

ia

l

Te

n

si

o

n

(l

b

s.)

(r

ef

.)

WA

S

H

/ 2

SPE

E

D

WASH

5

0

C

5

/1

6

6

.6

– 9.

2

K

P3

5.

1 – 7.

1

K

N

1

3/

3

2

2.

4 – 2.

8

D

P2

2 – 2.

4

D

N

6

0

C

1

1/

3

2

2

.4

–

2

.8

4

D

P

2

2

.0

– 2.

4

D

N

1

3/

3

2

2.

4 – 2.

8

D

P2

2 – 2.

4

D

N

D

R

A

IN

5

0

C

5

/16

9.

6 – 13

.0

MP

3

7

.4

– 10

.0

MN

25

/6

4

9

.6

– 13

.0

MP

3

7

.4

–

1

0

.0

MN

6

0

C

1

1/

3

2

2.

8 – 4.

0

E

P2

2

.4

–

3

.3

7

E

N

1

3

/3

2

2

.8

– 4.

0

E

P2

2.

4 – 3.

4

E

N

HIGH

SPE

E

D

EXT

R

AC

T

50

C

2

5

/64

10

.5

–

1

4

.3

N

P

3

8

.1

–

11

.0

N

N

27

/6

4

1

0

.5

–

1

4

.3

N

P

3

8

.1

–

11

.0

N

N

60

C

2

5

/64

8.

0 – 11

.0

L

P

3

6

.2

–

8

.5

L

N

2

7

/64

9.

6 – 13

.0

MP

3

7

.4

– 10

.0

MN

LOW

SPE

E

D

EXT

R

AC

T

50

C

1

1

/64

9.

0 – 13

.0

MP

3

7

.4

– 10

.0

MN

11

/6

4

6.

6 – 9.

2

K

P3

5.

1 – 7.

1

K

N

60

C

5

/3

2

1

1

/64

Ï

36026QWE 42026QWE

Be

lt

Def

lect.

(i

nches)

Init

ia

l

Te

n

si

o

n

(l

bs

.)

(

ref.

)

Init

ia

l

T

ension (

lbs.)

(ref

.)

Be

lt

Deflect

(I

N)

Init

ia

l

Tensio

n

(l

bs

.)

(ref

.)

Init

ia

l

Te

n

si

o

n

(l

b

s.)

(r

ef

.)

WA

S

H

/ 2

SPE

E

D

WASH

50

C

1

3

/32

2.

4 – 2.

84

D

P

2

2

.0

–

2

.4

D

N

11

/3

2

9

.6

– 13

.0

MP3

7.

4 – 10

.0

MN

60

C

1

3

/32

23

/6

4

2.

8 – 4.

0

D

R

A

IN

5

0

C

25

/6

4

9

.6

– 13

.0

MP

3

7

.4

– 10

.0

MN

23

/6

4

EP2

2

.4

– 3.

4

E

N

6

0

C

1

3/

3

2

2.

8 – 4.

0

E

P2

2

.4

–

3

.3

4

E

N

2

3

/6

4

1

0.

5 – 14

.3

HIGH

SPE

E

D

EXT

R

AC

T

50

C

7

/1

6

9

.6

– 13

.0

MP

3

7

.4

– 10

.0

MN

7

/16

9.

6 – 13

.0

N

P

3

8

.1

– 11

.0

N

N

60

C

7

/1

6

8

.0

– 11

.0

L

P

3

6

.2

–

8

.5

L

N

7

/1

6

9

.6

– 13

.0

MP

3

7

.4

– 10

.0

MN

LOW

SPE

E

D

EXT

R

AC

T

50

C

3

/1

6

9.

6 – 13

.0

MP

3

7

.4

– 10

.0

MN

1/

4

6.

6 – 9.

2

MP

3

7

.4

– 10

.0

MN

6

0

C

3

/1

6

1

/4

KP3

5

.1

–

7

.1

K

N

Ï

42

02

6Q

HE, Q

T

G, Q

T

H

Be

lt

D

ef

l.

(i

nches)

Init

ia

l Tensio

n

(l

b

s.)

(

re

f.

)

F

ina

l T

ension

(l

b

s.)

(r

ef

.)

WA

S

H

/

2

SPE

E

D

WASH

19

/6

4

9

.6

2 – 13

.0

M

P

3

7

.4

– 10

.0

M

N

D

R

A

IN

5

/3

2

1

0.

5 – 14

.3

8.

1 – 11

.0

M

A

IN

5

0

C

3

1

/64

1

0

.5

– 14

.3

N

P

3

8

.1

– 11

.0

N

N

60

C

1

5/

3

2

OPTI

ONAL LOW

S

P

E

ED

EX

R

A

CT

1

9

/6

4

8

.0

– 11

.0

LP

3

6

.2

– 8.

5

L

N

Upper

o-

ri

ng

Deflec

tion

F

o

rc

e Sc

ale

(R

ead Down)

Deflec

tion Dis

-

tance Sc

ale

(R

ead Up)

Lower

o-

ri

ng

Î

FIG

URE 1

(M

SSM0

2

0

4

AE)

Î

Tensi

on Tester

Scal

es

Lower

o-

ri

ng

Str

a

ight

Edge

Î

FI

GURE 2

(M

SSM

0

2

0

4

AE)

Î

Taking Measur

em

ents

w

ith the

Tensi

on Tester

2