Step 4. determine required cfm of each machine – Woodstock SHOP FOX W1808 User Manual

Page 34

-32-

W1808/W1809/W1810 Cyclone Dust Collectors

O

PE

R

AT

IO

N

S

Step 4. Determine Required CFM of Each

Machine

Since each machine produces a different amount of saw-

dust, the requirements for the minimum amount of CFM

to move that sawdust is unique to the machine (for exam-

ple, a planer produces more sawdust than a table saw).

Knowing this required CFM is important to gauging which

size of duct to use.

Figure 47 will give you a close estimation of the airflow

your machine requires. Keep in mind that machines that

generate the most sawdust should be placed closest to

the dust collector. If the machine has multiple dust ports,

the total CFM required is the sum of all ports.

If your machine doesn't have a built in dust port, use

Figure 46 to determine which size of dust port to install

on your machine.

Machine

Dust Port Size

Approximate

Required CFM

2"

98

2.5"

150

3"

220

4"

395

5"

614

6"

884

7"

1203

8"

1570

9"

1990

10"

2456

Figure 47. Approximate required airflow

for machines, based on dust port size.

���

���

���

���

���

���

��

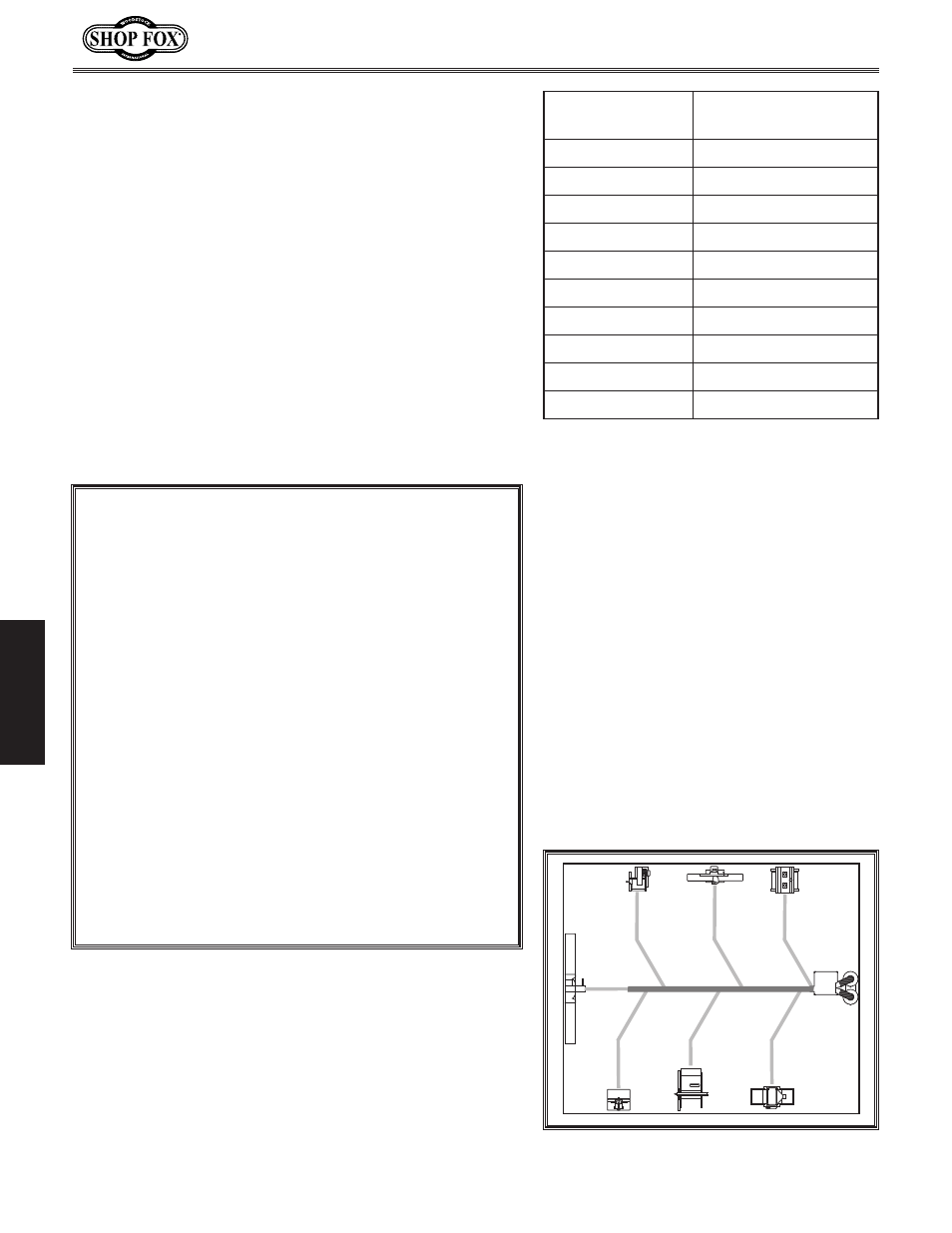

Figure 48. CFM requirements labeled for

each machine.

Write the required CFM for each machine on your sketch,

as shown in

Figure 48.

Machine

Average Dust Port Size

Table Saw

4"

Miter/Radial-Arm Saw

2"

Jointer (6" and smaller)

4"

Jointer (8"-12")

5"

Thickness Planer (13" and smaller)

4"

Thickness Planer (14"-20")

6"

Shaper

4"

Router (mounted to table)

2"

Bandsaw

4"

Lathe

4"

Disc Sander (12" and smaller)

2"

Disc Sander (13-18")

4"

Belt Sander (6" and smaller)

2"

Belt Sander (7"-9")

3"

Edge Sander (6" x 80" and smaller)

4"

Edge Sander (6" x 80" and larger)

5"

Drum Sander (24" and smaller)

2 x 4"

Drum Sander (24" and larger)

4 x 4"

Widebelt Sander (18" and smaller)

5"

Widebelt Sander (24"–37" single head)

2 x 6"

Widebelt Sander (24"_51" double head)

5 x 4"

Figure 46. Dust port size and quantity per average

machine.