Aligning.wheels – Woodstock SHOP FOX W1706 User Manual

Page 49

-47-

Model W1706 (Mfg. Since 3/13)

SE

RV

IC

E

Tool.Needed.

Qty

Wrench or Socket 10mm .......................................1

The.skew.the.table,.do.these.steps:

1. On a scrap piece of wood, mark a line that is

perpendicular to the front edge. Starting where the

line begins, cut the board by pushing it through the

blade with the miter gauge.

2. Loosen the six trunnion bolts that secure the table

(see

Figure.60). Shift the table to compensate

for the difference between the cut edge of the

workpiece and the mark you made in

Step.1.

Note:.Keep in mind that as the table alignment is

changed, so is the fence alignment.

3. Repeat

Steps.1–2 until the blade cuts straight when

wood is pushed through with the miter gauge.

4. Re-tighten the trunnion bolts to secure the setting.

Figure.60. Location of trunnion bolt.

Trunnion Bolt

(1 of 6)

Aligning.Wheels

Wheel alignment is one of the easiest ways to ensure

you get optimal performance from your bandsaw. When

wheels are aligned, or coplanar, the bandsaw is more

likely to cut straight without wandering; and vibration,

heat, and blade wear are considerably decreased because

the blade is automatically balanced on the wheel. This is

known as “Coplanar Tracking.”

Tools.Needed.

Qty

Wrench or Socket 10mm .......................................1

Wrench or Socket 13mm .......................................1

Wrench or Socket

3

⁄

4

" ..........................................1

Straightedge 48" ................................................1

Fine Ruler ........................................................1

Shim Washers ........................................ As needed

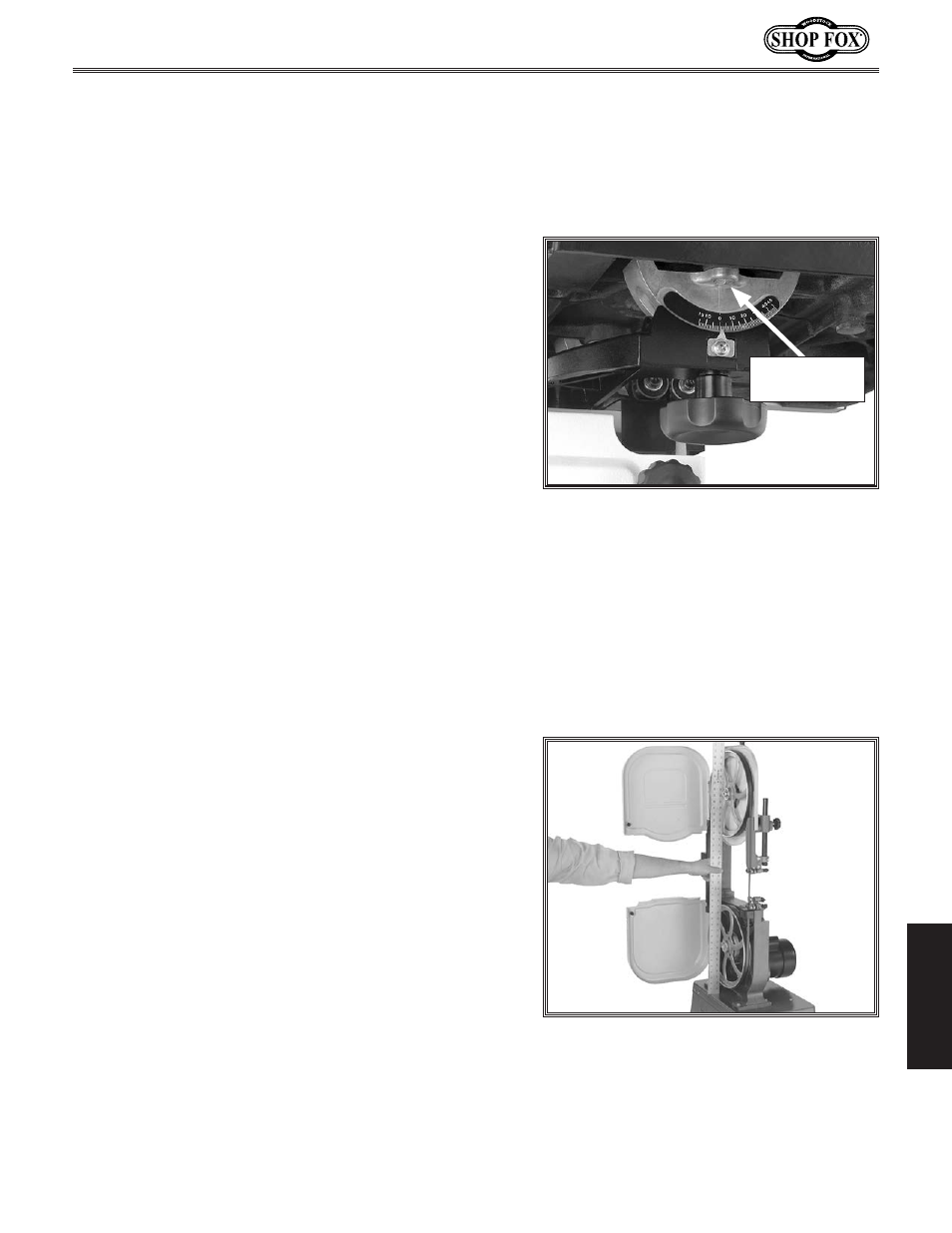

To.verify.if.the.upper.and.lower.wheels.are.coplanar,.

do.these.steps:

1. DISCONNECT BANDSAW FROM POWER!

2. Remove the table and open both wheel covers.

Figure.61. Checking wheel alignment with

a straightedge.