Maintenance schedule, 0 maintenance – Ingersoll-Rand NIRVANA IRN75-160K-2S User Manual

Page 82

IRN37 - 160K - CC & IRN50 - 200H -CC & IRN75 - 160K - 2S & IRN100 - 200H - 2S & IRN 250 - 300H - 2S

http://air.irco.com

0

10.0 MAINTENANCE

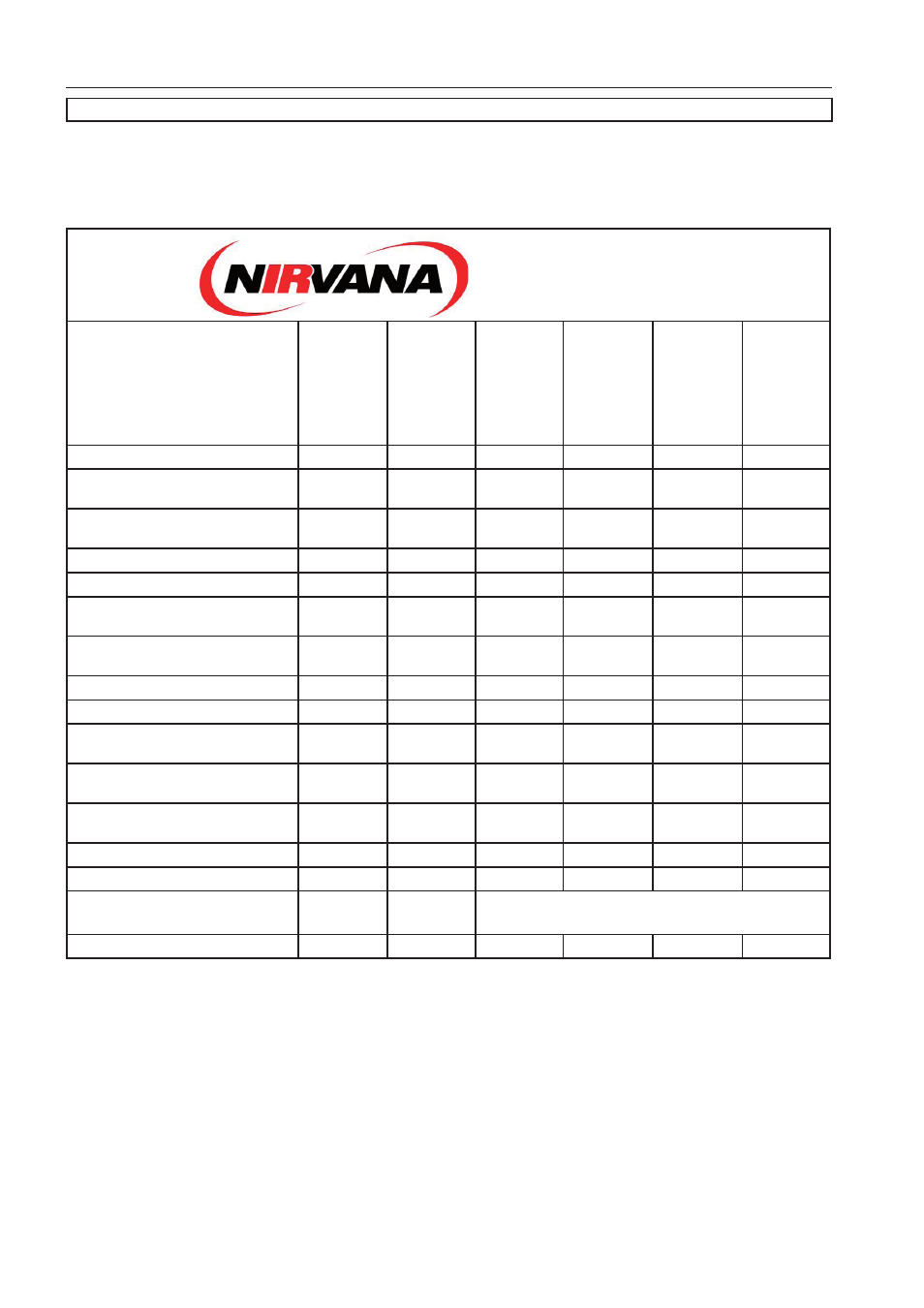

10.2 MAINTENANCE CHART

The MAINTENANCE CHART indicates the various components and the intervals when maintenance has to take place.

Where a service interval is stated in both hours and months, it is the sooner of the two intervals that must be adhered

to. Coolant capacities etc can be found in the GENERAL INFORMATION section of this manual. Note that any Local or

National codes that require specific maintenance that exceeds the requirements of this section must be adhered to.

™

Maintenance Schedule

Hours:

Daily

150

(1st time

only)

500

1000

1500

2500

3000

2000

6000

10000

14000

18000

4000

12000

20000

8000

16000

Coolant filter

Change

Change

Change

Change

Air filter **

Check

pressure

Change

Change

Separator element ***

Check

pressure

Change

Change

ULTRA COOLANT*

Check

Sample

Sample

Change

Power Drive Module filter *

Check

Change

Change

Change

Scavenge screen **

Check /

clean

Check /

clean

Check /

clean

Hoses ***

Check /

clean

Check /

clean

High Air Temperature sensor

Check

Check

Check

Check

Pressure relief valve

Check

Check

Check

Cooler Core(s)

Check /

clean

Check /

clean

Check /

clean

Check /

clean

Moisture separator

Check /

clean

Check /

clean

Check /

clean

Check /

clean

Motor cowl

Check /

clean

Check /

clean

Check /

clean

Check /

clean

Vibration Analysis

Analysis

Analysis

Analysis

Coolant Analysis

Analysis

Analysis

Analysis

Food Grade Coolant *

Analysis at every 500

Change at every 1000

Blower Motor / Fan Motor

Regrease

Regrease

If the compressor is run less than 4,000 hours per year,

HPM 250L motor Regrease at 2000hrs and 4000hrs N250/300H-2S only

* Maintain every 6 months

** Maintain every year

*** Maintain every 2 years